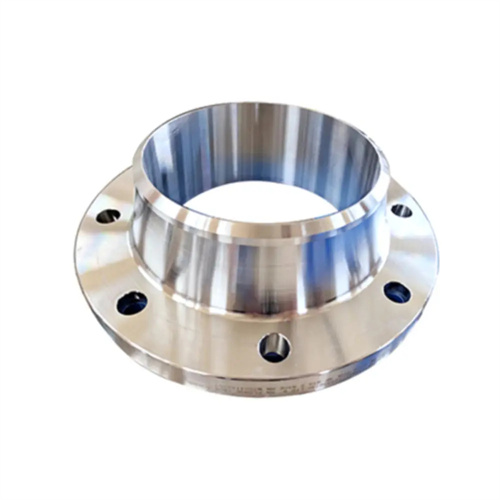

Stainless Steel Forging

Stainless steel forging is a manufacturing process that involves shaping stainless steel into desired components using compressive forces, typically at high temperatures. Stainless steel is an iron-based alloy containing a minimum of 10.5% chromium, which provides excellent corrosion resistance, strength, and durability. The forging process enhances the mechanical properties of stainless steel by refining its grain structure, resulting in components with superior strength, toughness, and resistance to wear and fatigue.

Stainless steel forging can be performed using various techniques, including hot forging, cold forging, and hot press forging, depending on the application requirements. The process is widely used in industries that require components capable of withstanding harsh environments, such as high temperatures, corrosive chemicals, and heavy loads.

Advantages of Stainless Steel Forging

Corrosion Resistance: Stainless steel’s chromium content forms a passive oxide layer that protects it from rust and corrosion, making it ideal for use in harsh environments.

High Strength and Durability: Forged stainless steel components offer exceptional strength, toughness, and resistance to wear and fatigue.

Aesthetic Appeal: Stainless steel has a smooth, polished surface that is visually appealing and easy to clean, making it suitable for applications where appearance matters.

Temperature Resistance: Stainless steel retains its mechanical properties at both high and low temperatures, making it suitable for extreme conditions.

Hygienic Properties: Stainless steel is non-porous and easy to sterilize, making it ideal for applications in the food, medical, and pharmaceutical industries.

Customizability: Stainless steel forging allows for the production of custom parts with complex geometries and precise dimensions.

Applications of Stainless Steel Forging

Energy Industry

In the energy industry, stainless steel forging is used to produce components for power generation, oil and gas extraction, and renewable energy systems. These components must endure high temperatures, pressure, and corrosive environments.

Turbine Shafts and Blades: Forged stainless steel turbine shafts and blades are used in power plants and wind turbines, offering high strength and resistance to thermal fatigue and corrosion.

Valves and Fittings: Stainless steel forged valves and fittings are used in oil and gas pipelines, providing durability and leak-proof performance under high pressure and corrosive conditions.

Heat Exchangers: Forged stainless steel heat exchangers are used in power plants and refineries to efficiently transfer heat while resisting corrosion.

Construction

In the construction industry, stainless steel forging is used to produce durable and corrosion-resistant components for buildings, bridges, and infrastructure projects. Stainless steel’s strength and aesthetic appeal make it ideal for structural and decorative applications.

Structural Components: Forged stainless steel beams, columns, and fasteners provide the strength and durability needed for modern construction while resisting corrosion from environmental exposure.

Bridges and Railings: Stainless steel forged components are used in bridges and railings due to their ability to withstand harsh weather conditions and maintain their appearance over time.

Architectural Features: Forged stainless steel is used for decorative elements such as sculptures, facades, and handrails, combining strength with aesthetic appeal.

Power Equipment

The power equipment industry uses stainless steel forging to manufacture components for generators, transformers, and other electrical systems. These components must deliver reliable performance under high electrical and mechanical stress.

Generator Rotors: Forged stainless steel rotors are used in generators to convert mechanical energy into electrical energy, offering high strength and resistance to deformation and corrosion.

Transformer Cores: Stainless steel forged cores are used in transformers to enhance magnetic properties and ensure efficient energy transfer.

Circuit Breakers: Forged stainless steel components in circuit breakers provide the strength and durability needed to handle high electrical currents and ensure safety.

Hardware Tools

The hardware tools industry benefits from stainless steel forging to produce durable and corrosion-resistant tools that enhance performance and longevity. Stainless steel forged tools are ideal for both professional and DIY applications.

Wrenches and Sockets: Forged stainless steel wrenches and sockets are strong, durable, and resistant to rust, making them suitable for heavy-duty use in various environments.

Pliers and Cutters: Stainless steel forged pliers and cutters provide the strength and precision needed for various cutting and gripping tasks, even in corrosive conditions.

Tool Handles: Forged stainless steel handles for hammers, screwdrivers, and other tools offer a comfortable grip and long-lasting performance.

Stainless steel forging is a highly versatile and efficient manufacturing process that offers numerous advantages, including corrosion resistance, high strength, and aesthetic appeal. Its unique properties make it an ideal choice for a wide range of applications across various industries. In the energy industry, stainless steel forging is used to produce turbine components, valves, and heat exchangers. In construction, it provides durable and corrosion-resistant structural and decorative components. The power equipment industry relies on stainless steel forged parts for generators and transformers, while the hardware tools industry benefits from its durability and corrosion resistance.

As a manufacturer, leveraging the capabilities of stainless steel forging can help you deliver high-quality, durable, and cost-effective components that meet the specific needs of your customers. Whether you are producing parts for energy infrastructure, construction projects, power equipment, or hardware tools, stainless steel forging offers a reliable solution for achieving superior results. Its ability to withstand harsh environments and deliver long-lasting performance makes it a cornerstone of modern industrial manufacturing.