Alloy Steel Forging: Raw Material Inspection Protocols

The first line of quality control in alloy steel forging begins with stringent raw material inspection. We implement rigorous protocols to verify the chemical composition and mechanical properties of incoming alloy steel billets before production. Each batch undergoes spectrographic analysis to confirm alloying elements like chromium, molybdenum, and nickel meet exact specifications—critical for ensuring the final forged components achieve required strength and durability. We also perform ultrasonic testing on raw materials to detect internal defects such as cracks or inclusions that could compromise forging integrity. Tensile testing on sample coupons verifies that the base material meets minimum strength requirements. By cross-referencing material certificates with our own test results, we ensure complete traceability from the steel mill to our forging facility. This meticulous raw material validation prevents substandard materials from entering production, establishing a solid foundation for quality alloy steel forgings.

Alloy Steel Forging: Process Parameter Monitoring Standards

Maintaining strict process parameter controls is essential for consistent quality in alloy steel forging production. We establish precise standards for key variables throughout the forging cycle, including heating temperatures, press pressure, deformation rates, and hold times. Our computerized monitoring systems track these parameters in real-time, with automatic alerts triggering if values deviate from predefined tolerances. For example, we maintain forging temperatures within ±15°C of target values to ensure proper material flow without grain growth. Pressure settings on hydraulic presses are calibrated daily and verified using load cells during production runs. We document every parameter for each forging batch, creating a comprehensive process history that enables root cause analysis if quality issues arise. By standardizing these parameters across all production lines, we ensure that each alloy steel forging—whether produced on Monday or Friday—meets identical quality benchmarks, eliminating variability that could affect performance.

Alloy Steel Forging: Dimensional Accuracy Verification Methods

Dimensional accuracy is a cornerstone of quality control in alloy steel forging, requiring standardized verification methods. We employ coordinate measuring machines (CMMs) with micron-level precision to inspect critical dimensions of every forged component against engineering drawings. For high-volume production, we use automated vision systems that perform 100% inspection of key features like hole positions, flange thicknesses, and overall part geometry. We establish clear tolerance standards based on component function—typically ±0.05mm for precision aerospace forgings and ±0.1mm for industrial components. Statistical process control (SPC) charts track dimensional variation over production runs, alerting us to trends that might indicate die wear or process drift. We also verify form and profile characteristics using gauges specifically designed for each component, ensuring that complex features like gear teeth or splines meet functional requirements. These dimensional verification standards guarantee that forged components will assemble correctly and perform as designed in their final applications.

Alloy Steel Forging: Non-Destructive Testing Requirements

Non-destructive testing (NDT) forms a critical part of our quality control standards for alloy steel forgings. We mandate ultrasonic testing for all critical load-bearing components to detect internal defects like voids, cracks, or inclusions that could reduce structural integrity. Magnetic particle inspection is standard for identifying surface and near-surface discontinuities in ferromagnetic alloy steels, particularly effective for detecting fatigue cracks in high-stress areas. For components requiring exceptional reliability—such as power generation turbine shafts—we perform radiographic testing to examine internal structures that ultrasonic methods might miss. We’ve established clear acceptance criteria for NDT results, defining maximum allowable defect sizes based on component application and industry standards like ASTM E1444 for ultrasonic testing. All NDT operators are certified to ASNT standards, ensuring consistent interpretation of results. By making NDT a mandatory step, we identify potential flaws without damaging the forged components, maintaining both quality and production efficiency.

Alloy Steel Forging: Mechanical Property Validation Standards

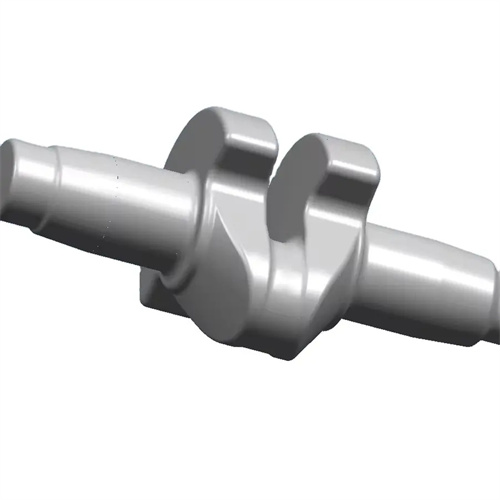

Validating mechanical properties ensures alloy steel forgings meet performance requirements in real-world applications. We conduct destructive testing on sample components from each production batch, including tensile testing to verify yield strength and elongation, impact testing to assess toughness, and hardness testing to confirm heat treatment effectiveness. For heat-treated forgings, we use Rockwell or Brinell hardness tests at multiple locations to ensure uniform properties throughout the component. We’ve developed specific standards for different alloy grades—for example, requiring 4140 alloy steel forgings to achieve a hardness range of 28-32 HRC for structural applications. Fatigue testing is performed on critical components like automotive crankshafts or aerospace landing gear parts, simulating thousands of load cycles to verify durability. These mechanical property tests are not just pass/fail checks; they provide valuable data that we use to refine our forging and heat treatment processes, continuously improving the quality of our alloy steel forgings.

Alloy Steel Forging: Documentation and Compliance Standards

Comprehensive documentation and compliance with industry standards form the backbone of our quality control system for alloy steel forging. We maintain detailed records for each production batch, including material certifications, process parameters, inspection results, and test data—creating a complete traceability trail from raw material to finished product. These documents are stored electronically for at least 10 years, meeting regulatory requirements for industries like aerospace and oil & gas. We align our quality standards with international specifications such as ISO 9001, ASTM F29 Standard, and NADCAP requirements for aerospace components. Regular internal and third-party audits verify that our quality control processes adhere to these standards, with corrective action plans implemented for any non-conformances. By standardizing documentation practices and maintaining strict compliance, we provide customers with the confidence that our alloy steel forgings meet not just their specifications, but also the most rigorous industry quality and safety standards.