Alloy Steel Forging: Grain Structure Enhancement for Superior Strength

One of the primary advantages of alloy steel forging in high-strength applications lies in its ability to optimize grain structure. When we forge alloy steel, we subject the material to controlled deformation at elevated temperatures, which compresses and realigns its internal grains. This process eliminates voids and creates continuous grain flow that follows the component’s contours, distributing stress more effectively across the part. Unlike cast components with random grain patterns or machined parts with interrupted grain structures, forged alloy steel develops a uniform, dense microstructure that resists deformation under heavy loads. In applications like industrial crane hooks or offshore drilling equipment, this enhanced grain structure translates to up to 40% higher tensile strength compared to alternative manufacturing methods. We’ve observed that properly forged alloy steel components maintain structural integrity even when operating near their maximum load capacity, making them indispensable for safety-critical high-strength applications.

Alloy Steel Forging: Exceptional Fatigue Resistance for Longevity

Alloy steel forging provides superior fatigue resistance, a critical advantage in high-strength applications involving repeated stress cycles. The directional grain flow created during forging allows the material to withstand thousands of load cycles without developing cracks—a common failure mode in components like automotive axles, wind turbine shafts, and hydraulic cylinders. When we compare forged alloy steel to cast or welded alternatives, we consistently find that forged parts exhibit 2-3 times longer fatigue life in high-stress environments. This resistance stems from the forging process’s ability to eliminate internal defects that act as fatigue initiation points, combined with the aligned grain structure that dissipates stress concentrations. By controlling forging parameters like temperature, pressure, and deformation rate, we tailor each component’s fatigue resistance to its specific application, ensuring reliable performance in high-strength scenarios where failure could have catastrophic consequences.

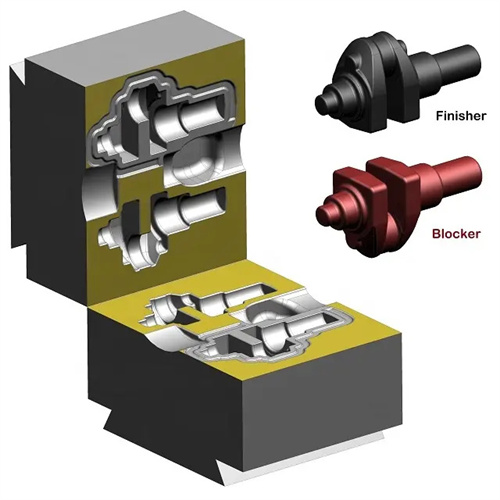

Alloy Steel Forging: Design Flexibility for Complex High-Strength Components

Alloy steel forging offers unmatched design flexibility for creating complex high-strength components that would be difficult or impossible to produce with other methods. We can forge intricate geometries—including internal cavities, thin walls, and complex contours—while maintaining uniform strength throughout the part. This flexibility allows engineers to optimize component designs for both strength and weight, critical in applications like aerospace landing gear or military vehicle suspensions where every kilogram matters. Unlike casting, which often requires draft angles and thick sections, forging enables us to create sharp corners and variable wall thicknesses in high-stress areas without sacrificing strength. We frequently integrate multiple features—such as flanges, bosses, and mounting surfaces—into a single forged component, eliminating the need for welding or assembly that could create weak points. This design versatility ensures that high-strength alloy steel components can meet both performance requirements and geometric complexity.

Alloy Steel Forging: Temperature and Corrosion Resistance in Extreme Environments

High-strength applications often operate in extreme environments, and alloy steel forging enhances both temperature and corrosion resistance. By selecting appropriate alloy compositions and optimizing forging parameters, we create components that maintain strength at elevated temperatures—critical for applications like power plant turbines or industrial furnace hardware. For example, our forged chromium-molybdenum alloy steel components retain over 90% of their room-temperature strength at 500°C, far outperforming cast alternatives. Additionally, the dense, defect-free structure of forged alloy steel minimizes pathways for corrosive agents to penetrate, while alloying elements like nickel and chromium form protective oxide layers. In offshore oil rig components or chemical processing equipment, we’ve found that properly forged and heat-treated alloy steel resists corrosion up to 50% better than machined parts of the same alloy grade, ensuring long-term performance in harsh, high-strength environments.

Alloy Steel Forging: Cost-Effective High-Strength Solutions at Scale

While alloy steel forging requires higher initial tooling investment, it delivers cost-effective high-strength solutions at production scale. In high-volume high-strength applications like automotive transmission components or construction equipment parts, we achieve significant cost savings through reduced material waste and minimal post-processing. Forging shapes metal through deformation rather than removal, typically using 70-80% of the raw material compared to machining. The enhanced mechanical properties of forged alloy steel also reduce the need for expensive material upgrades—we can often meet high-strength requirements with standard alloy grades through optimized forging rather than costly specialty materials. Additionally, the longer service life of forged components reduces replacement and maintenance costs over the product lifecycle. In our experience, for high-strength applications with production volumes exceeding 1,000 units, alloy steel forging becomes the most economical manufacturing method while delivering superior performance.

Alloy Steel Forging: Consistency and Reliability in Critical Applications

Consistency and reliability are paramount advantages of alloy steel forging in high-strength applications where performance variation could lead to failure. We implement strict process controls throughout forging—monitoring temperature, pressure, and deformation to ensure every component meets identical specifications. This consistency results in uniform mechanical properties across production runs, with typical variation in tensile strength below 5% compared to 15-20% in cast components. For critical applications like nuclear reactor components or aerospace fasteners, this reliability is non-negotiable. The forging process also enables complete traceability from raw material to finished part, with documentation of every production step ensuring compliance with stringent industry standards. We’ve found that customers in high-strength industries value this consistency as much as the material’s strength itself, as it allows for more accurate performance predictions and safer operation in demanding environments where reliability cannot be compromised.