Aluminum Forging: Raw Material Inspection Protocols

The foundation of quality in aluminum forging begins with rigorous raw material inspection. Before any forging process, we subject aluminum billets to comprehensive testing to verify chemical composition and initial mechanical properties. Using spectrographic analysis, we confirm that alloying elements like copper, magnesium, and zinc meet exact specifications—critical for ensuring the final forged parts achieve target strength levels. We also perform ultrasonic testing on incoming billets to detect internal defects such as cracks or inclusions that could compromise forging integrity. Tensile testing on sample coupons from each billet lot verifies baseline strength and ductility. For aerospace-grade aluminum forgings, we implement additional checks, including microstructure analysis to assess grain size and uniformity. By establishing strict acceptance criteria for raw materials and maintaining complete traceability from supplier to production, we ensure only quality aluminum enters our forging processes, preventing downstream defects and ensuring consistent part performance.

Aluminum Forging: In-Process Quality Monitoring

In-process monitoring is essential for maintaining quality standards during aluminum forging operations. We use real-time sensors to track critical parameters including billet temperature, press pressure, deformation rate, and die alignment throughout the forging cycle. These measurements are continuously compared against predefined process windows, with automatic alerts triggering if deviations occur—allowing immediate adjustments to prevent defect formation. For closed-die forging, we inspect dies regularly for wear or damage using coordinate measuring machines (CMMs), ensuring they maintain the precision required for tight-tolerance parts. We also perform visual inspections of each forged part immediately after pressing, checking for surface defects like cracks, laps, or incomplete filling of die cavities. By documenting every process parameter and inspection result, we create a comprehensive quality record for each aluminum forging batch, enabling root cause analysis if issues arise and ensuring consistent process control across all production runs.

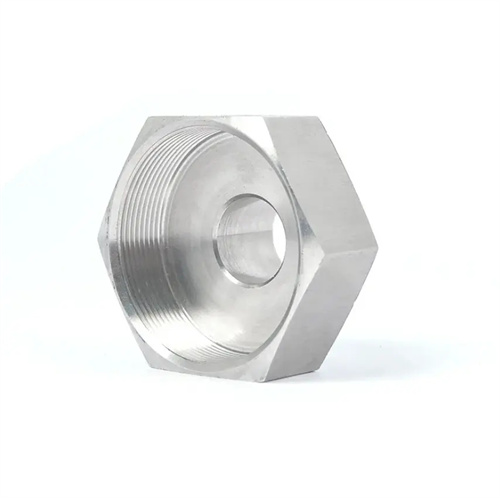

Aluminum Forging: Dimensional Accuracy Verification

Ensuring dimensional accuracy is a cornerstone of quality assurance in aluminum forging. We employ a tiered inspection approach, starting with go/no-go gauges for rapid verification of critical features like hole positions and overall dimensions. For more precise measurements, we use CMMs with laser scanning capabilities to inspect complex geometries, generating detailed reports that compare actual dimensions against engineering drawings. These systems can detect deviations as small as ±0.0005 inches, ensuring aluminum forgings meet the tight tolerances required for aerospace and automotive applications. Statistical process control (SPC) charts track dimensional variation over production runs, alerting us to trends that might indicate die wear or process drift. For high-volume production, we implement automated vision systems that perform 100% inspection of key features, ensuring no out-of-tolerance parts proceed to subsequent operations. This rigorous dimensional verification guarantees that aluminum forgings will assemble correctly and function as designed in their final applications.

Aluminum Forging: Non-Destructive Testing Methods

Non-destructive testing (NDT) plays a vital role in verifying internal quality without damaging aluminum forgings. We use ultrasonic testing as the primary method for detecting subsurface defects like voids, cracks, or inclusions in all critical load-bearing components. This technique uses high-frequency sound waves to identify discontinuities that could reduce structural integrity, with results interpreted by certified Level II or III inspectors. For surface defect detection, we employ magnetic particle inspection for ferromagnetic aluminum alloys and dye penetrant testing for non-ferromagnetic materials, ensuring we identify even microscopic surface cracks. For aerospace aluminum forgings, we often perform radiographic testing on complex geometries to examine internal structures that ultrasonic methods might miss. All NDT procedures follow industry standards such as ASTM E1444 for ultrasonic testing and ASTM E165 for penetrant inspection, with clear acceptance criteria defined based on part application and criticality.

Aluminum Forging: Mechanical Property Testing Requirements

Mechanical property testing ensures aluminum forgings meet the strength and performance requirements for their intended applications. We conduct tensile testing on sample forgings from each production batch, measuring ultimate tensile strength, yield strength, and elongation to verify they fall within specified ranges—typically 30,000-70,000 psi for common aluminum alloys used in forging. Hardness testing using Rockwell or Brinell methods provides rapid verification of heat treatment effectiveness, with measurements taken at multiple locations on each test sample to ensure uniformity. For components subject to repeated loading, we perform fatigue testing to determine the forging’s endurance limit, simulating real-world operating conditions. Impact testing, including Charpy and Izod methods, evaluates toughness and resistance to sudden loading. These tests are not just pass/fail checks; the data collected helps us refine forging and heat treatment processes, ensuring continuous improvement in aluminum forging quality. Test results are documented and retained as part of the forging’s quality record, providing traceability for regulatory compliance.

Aluminum Forging: Compliance with Industry Standards and Certifications

Adherence to recognized industry standards and certifications forms the framework of our quality assurance program for aluminum forging. We maintain compliance with international standards including ISO 9001 for quality management and ISO 13485 for aerospace applications, ensuring our processes meet global quality requirements. For automotive aluminum forgings, we follow IATF 16949 standards, which include additional controls for product safety and traceability. Our quality management system incorporates regular internal audits and third-party assessments to verify compliance with these standards and our own quality objectives. We also maintain certifications specific to critical industries, such as NADCAP accreditation for aerospace forging processes. By aligning our quality assurance practices with these established standards, we provide customers with confidence that our aluminum forgings meet or exceed industry requirements for performance, reliability, and safety. These certifications also facilitate market access for our forgings in regulated industries worldwide.