Hot Press Forging: Raw Material Preparation and Billet Sizing

The first step in hot press forging high-performance components involves meticulous raw material preparation and precise billet sizing. We start by selecting high-quality billets with verified chemical compositions matching the application’s requirements—critical for ensuring proper forging behavior and final mechanical properties. Using sawing or shearing equipment, we cut billets to exact dimensions based on the part’s volume and the die cavity size, typically leaving a 5-10% material allowance to account for flash formation. Each billet undergoes surface cleaning to remove oxides, scale, or contaminants that could affect forging quality or damage dies. For high-strength alloys like Inconel 718, we also inspect billets for internal defects using ultrasonic testing, rejecting any with subsurface inclusions. This preparation stage ensures uniform material flow during forging and prevents defects in the final component. Proper billet sizing directly impacts press capacity requirements and material utilization, making it a critical foundation for efficient hot press forging.

Hot Press Forging: Controlled Heating to Optimal Forging Temperature

Heating the billet to the precise forging temperature is a critical step in hot press forging that directly influences material flow and final part quality. We use computer-controlled furnaces—either induction, gas-fired, or electric—to heat billets uniformly to the optimal temperature range for their specific alloy. Aluminum alloys are heated to 350-500°C, carbon steels to 800-1,250°C, and nickel-based superalloys to 950-1,150°C, with temperature variations maintained within ±10°C. The heating rate is carefully controlled to prevent thermal shock, especially for high-carbon or high-alloy materials prone to cracking. We monitor temperatures continuously using pyrometers and thermal imaging to ensure uniformity throughout the billet, avoiding hot spots that could cause uneven deformation. For large components, we implement pre-heating stages to gradually raise temperatures, ensuring the entire billet reaches the target temperature before press entry. This controlled heating stage ensures the material achieves optimal plasticity for the forging process.

Hot Press Forging: Die Preparation and Lubrication Application

Before the hot press forging operation, we prepare and condition the dies to ensure proper part formation and extend tool life. We start by cleaning dies thoroughly to remove residual material, scale, or lubricant buildup from previous runs, which could cause surface defects or incomplete cavity filling. Dies are preheated to 200-400°C—depending on the material being forged—to reduce thermal shock and improve material flow into the cavity. Next, we apply a specialized lubricant to the die surfaces, selecting formulations compatible with the forging temperature and material. For high-temperature alloys, we use ceramic-based lubricants that withstand extreme heat without breaking down, while graphite-based lubricants work well for steel and aluminum. The lubricant application must be uniform to prevent uneven friction that could cause material flow issues or die galling. Proper die preparation ensures consistent part quality, reduces flash formation, and extends die life—critical factors for producing high-performance components efficiently.

Hot Press Forging: Press Setup and Parameter Configuration

Setting up the hot press and configuring optimal parameters is essential for achieving precise deformation and consistent quality in high-performance components. We begin by installing the preheated dies into the press, ensuring proper alignment using precision guides and shims to maintain parallelism within 0.001 inches per foot. The press is then calibrated to apply the required force—ranging from 100 to 5,000 tons depending on part size and material—with pressure sensors verifying accuracy. We program the press control system with the specific forging sequence, including ram speed (typically 50-200 mm/s), dwell time at maximum pressure (3-10 seconds), and release rate. For complex geometries, we configure multi-stage pressure profiles to ensure complete cavity filling without over-stressing thin sections. Safety systems are verified, including emergency stops and overload protection, to prevent equipment damage or operator injury. This setup stage ensures the hot press operates within the optimal parameters for the specific component and material, laying the groundwork for successful forging.

Hot Press Forging: Billet Transfer and Press Operation Execution

The core of the process involves transferring the heated billet to the press and executing the hot press forging operation with precise timing and control. Using robotic arms or tongs designed for high temperatures, we transfer the heated billet from the furnace to the lower die cavity quickly—typically within 15-30 seconds—to prevent excessive cooling below the optimal forging temperature. The press cycle initiates automatically, with the upper die descending to contact the billet and apply controlled pressure. As pressure increases, the material flows into the die cavity, filling all features including ribs, bosses, and complex geometries. We monitor the process in real-time using sensors that track force, displacement, and temperature, ensuring they match the programmed parameters. For critical components, we use in-die monitoring to verify complete cavity filling before releasing pressure. After reaching the target deformation, the press opens, and the forged part—still attached to the flash—is removed using extraction tools. This stage requires precise coordination to maintain temperature and pressure control, directly impacting part quality and material properties.

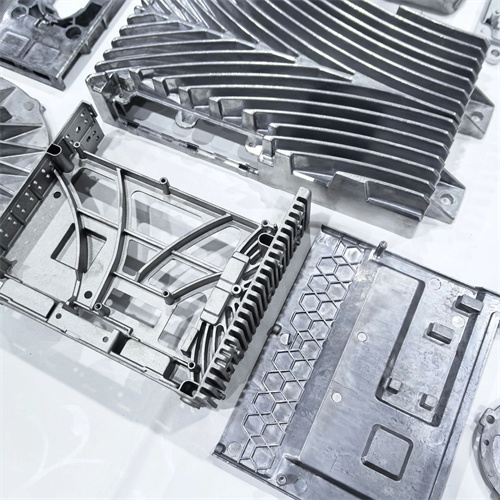

Hot Press Forging: Post-Forging Processing and Quality Inspection

The final step in hot press forging high-performance components involves post-forging processing and rigorous quality inspection to ensure compliance with specifications. Immediately after forging, parts may undergo controlled cooling or quenching depending on the material—water quenching for heat-treatable aluminum alloys or air cooling for carbon steels—to optimize microstructure development. Flash removal is performed using trimming presses or abrasive cutting tools to separate the excess material from the part. We then conduct initial visual inspections to check for surface defects like laps, seams, or cracks, followed by dimensional measurements using calipers, gauges, or CMMs to verify critical dimensions meet tolerances. For high-performance applications, additional testing includes ultrasonic inspection for internal defects, hardness testing to verify mechanical properties, and microstructure analysis on sample parts. Parts that pass inspection proceed to secondary operations like heat treatment or machining, while any non-conforming parts are analyzed for process improvement. This thorough post-forging stage ensures only high-quality components meet our standards for performance-critical applications.