Hot Press Forging: Enhancing Structural Integrity in Automotive Safety Components

Hot press forging plays a critical role in producing automotive safety components with superior structural integrity that protects passengers during collisions. We manufacture critical parts like steering knuckles, control arms, and axle beams using hot press forging, which creates a uniform grain structure that enhances impact resistance. These components must withstand extreme forces during accidents, and hot press forging ensures they maintain structural integrity when subjected to sudden loads. For example, hot press forged steering components exhibit 40% higher energy absorption than cast alternatives, reducing deformation in crash scenarios. The process also allows for complex geometries that integrate multiple safety features into single components, eliminating weak points from welded assemblies. In modern vehicles, including electric models, these hot press forged parts provide the strength needed to support heavier battery packs while maintaining crashworthiness standards, making them indispensable for automotive safety.

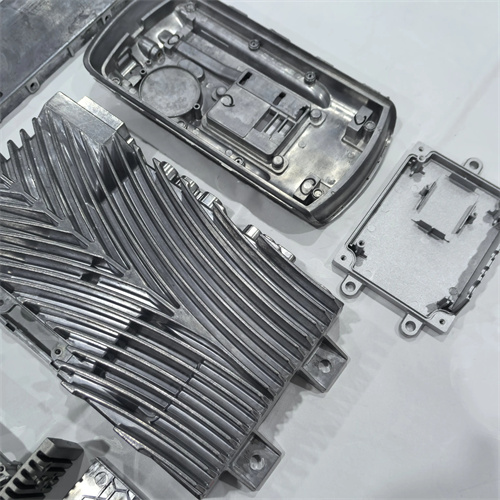

Hot Press Forging: Lightweight Solutions for Automotive Fuel Efficiency

In the automotive industry, hot press forging enables the production of lightweight, high-strength components that improve fuel efficiency and extend electric vehicle range. We use advanced alloys like 7000-series aluminum and high-strength low-alloy (HSLA) steels in hot press forging to create parts that are 20-30% lighter than traditional steel components without sacrificing strength. For electric vehicles, this weight reduction directly translates to extended battery range—typically 5-8% improvement for every 100kg reduced. Hot press forged aluminum suspension components reduce unsprung weight, improving handling and energy efficiency. The process also allows for material optimization, placing metal only where needed for strength while minimizing excess mass. In both traditional and electric vehicles, these lightweight hot press forged parts contribute to meeting stringent emissions regulations and consumer demands for better fuel economy.

Hot Press Forging: High-Temperature Performance in Aerospace Engines

Hot press forging is essential for producing aerospace engine components that perform reliably under extreme temperature conditions. We manufacture turbine disks, compressor blades, and combustion chamber parts using nickel-based superalloys and titanium alloys processed through hot press forging. These components operate at temperatures exceeding 1,000°C while withstanding centrifugal forces up to 10,000 Gs. Hot press forging creates a dense microstructure with directional grain flow that resists creep and thermal fatigue—critical for engine components with service lives of 30,000+ flight hours. The process allows us to forge complex airfoil shapes with precise cooling channels that maintain structural integrity at operating temperatures where standard manufacturing methods would fail. This high-temperature performance ensures aerospace engines operate efficiently and safely, making hot press forging indispensable for modern aviation propulsion systems.

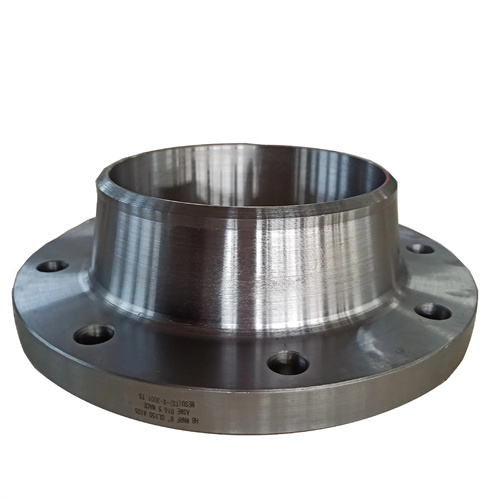

Hot Press Forging: Precision Components for Aerospace Structural Integrity

Aerospace airframes depend on hot press forged components to maintain structural integrity while minimizing weight. We produce critical structural parts like wing spars, landing gear components, and fuselage frames using hot press forging, which achieves the perfect balance of strength and weight. Hot press forged titanium alloy components offer the high strength-to-weight ratio required for airframe structures, withstanding aerodynamic loads and landing impacts over thousands of flights. The process enables tight tolerances (±0.005 inches) for critical fit features, ensuring proper alignment in airframe assemblies that reduces vibration and fatigue. For example, hot press forged landing gear struts must support 8-10 times the aircraft’s weight during landing, requiring the uniform material properties only achievable through controlled hot press forging. These precision components form the backbone of aerospace structures, ensuring safety and performance at 35,000 feet and beyond.

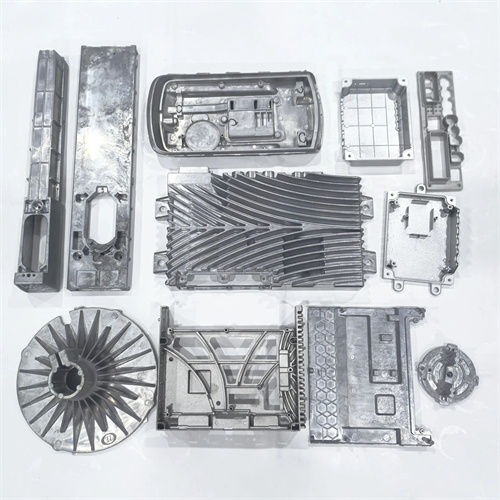

Hot Press Forging: Cost-Effective Production for High-Volume Automotive Parts

Hot press forging provides cost-effective production solutions for high-volume automotive components, balancing performance with manufacturing efficiency. We use automated hot press forging lines to produce parts like crankshafts, connecting rods, and transmission gears at volumes exceeding 100,000 units annually. The near-net-shape capability reduces material waste by 30-40% compared to machining from solid stock, lowering raw material costs. Hot press forging’s high production repeatability minimizes scrap rates to less than 2%, while extended die life (50,000+ parts per die set) reduces tooling costs. For automotive manufacturers, these efficiencies translate to lower per-unit costs for high-strength components that meet performance requirements. The process also integrates well with downstream automation, including robotic trimming and inspection, creating streamlined production flows that support just-in-time manufacturing models critical for automotive industry efficiency.

Hot Press Forging: Enabling Innovation in Next-Generation Vehicles and Aircraft

Hot press forging is driving innovation in next-generation automotive and aerospace vehicles by enabling new designs and materials. In electric and autonomous vehicles, we’re using hot press forging to develop integrated electric motor components that combine structural and functional features, reducing part counts by 30-50%. For urban air mobility vehicles and drones, hot press forged magnesium alloy components provide ultra-lightweight structures with enhanced crashworthiness. In aerospace, hot press forging supports the development of more fuel-efficient aircraft through advanced materials like metal matrix composites that can only be shaped using controlled hot press deformation. The process also enables the production of larger, more complex single-piece components that replace multi-part assemblies, reducing weight and improving reliability. As automotive and aerospace industries push toward electrification and increased efficiency, hot press forging continues to enable the performance breakthroughs needed for next-generation vehicles and aircraft.