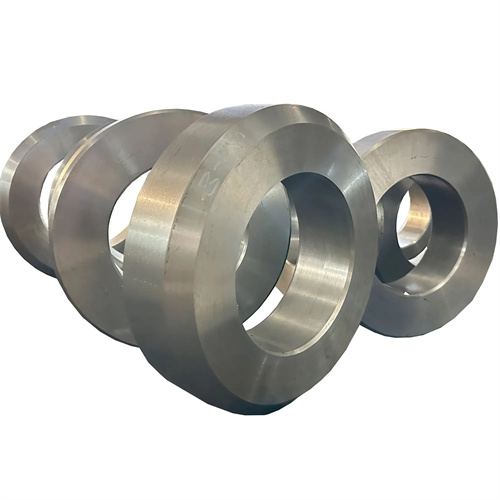

Stainless Steel Forging: Raw Material Selection and Preparation

The foundation of high-strength stainless steel forging begins with rigorous raw material selection and preparation. We source premium stainless steel billets with verified chemical compositions, ensuring alloying elements like chromium (16-18% for 304 grades) and nickel (8-10% for 316 grades) meet exact specifications to guarantee both strength and corrosion resistance. Before forging, each billet undergoes ultrasonic testing to detect internal defects that could compromise final strength, rejecting any with subsurface inclusions. We precisely cut billets to volume requirements, maintaining a 5-8% material allowance to ensure complete die filling during stainless steel forging. Surface preparation is critical: we remove oxides and contaminants using mechanical cleaning, preventing defects that could act as stress risers in the final component. This meticulous material preparation ensures consistent performance in the subsequent forging processes, forming the basis for high-strength stainless steel components.

Stainless Steel Forging: Precision Heating for Optimal Formability

Controlled heating is a critical process in stainless steel forging that directly impacts the strength of the final component. We heat stainless steel billets to precise temperatures within alloy-specific ranges: 1,100-1,250°C for austenitic grades like 304 and 316, and 850-1,050°C for martensitic grades such as 410. Using induction heating systems with temperature feedback loops, we maintain uniformity within ±5°C across the billet, preventing overheating that causes grain coarsening or underheating that increases forming stress. For high-strength 17-4 PH stainless steel, we use protective atmospheres during heating to minimize oxidation, preserving the material’s alloy content for optimal heat treatment response. The heating rate is carefully controlled—typically 5-10°C per second—to prevent thermal shock, especially for thick-section components. This precision heating ensures the stainless steel reaches optimal formability while maintaining the grain structure necessary for high-strength performance after forging.

Stainless Steel Forging: Controlled Deformation for Grain Structure Optimization

The deformation process in stainless steel forging is precisely controlled to optimize grain structure and enhance component strength. We use hydraulic presses with programmable force profiles, applying steady pressure (500-3,000 tons depending on part size) to ensure uniform material flow. For high-strength components, we implement multi-stage forging sequences that gradually shape the material, with intermediate annealing steps for work-hardening alloys to prevent cracking. The deformation rate is critical: 10-50 mm/s for austenitic stainless steels and slower rates (5-20 mm/s) for high-strength martensitic grades. This controlled deformation aligns grain structures along stress paths, creating directional strength that increases tensile properties by 20-30% compared to cast components. We monitor die fill in real-time using in-die sensors, ensuring complete deformation of critical sections that require maximum strength. This careful control of the deformation process ensures the stainless steel forging achieves the refined grain structure essential for high-strength applications.

Stainless Steel Forging: Die Design and Lubrication for Surface Integrity

Specialized die design and lubrication processes are essential in stainless steel forging to maintain surface integrity and dimensional accuracy in high-strength components. We engineer dies with precise draft angles (3-5°) and radii to facilitate material flow while minimizing stress concentrations in the final part. Die materials are selected for compatibility with stainless steel: hot work tool steels like H13 for austenitic grades and higher-alloyed tools for high-temperature super duplex forging. Lubrication is tailored to the stainless steel grade: graphite-based lubricants for lower-temperature forging and ceramic-based formulations for high-temperature alloys to prevent material adhesion. We apply lubricants uniformly using automated systems, ensuring consistent coverage that reduces friction and wear on both dies and workpieces. This attention to die design and lubrication results in stainless steel forged components with smooth surface finishes (Ra 1.6-3.2 μm) that minimize stress risers and enhance fatigue strength in high-strength applications.

Stainless Steel Forging: Post-Forging Heat Treatment for Strength Enhancement

Strategic heat treatment following stainless steel forging is critical for developing the high-strength properties required in demanding applications. For precipitation-hardening grades like 17-4 PH, we perform solution annealing at 1,040°C followed by aging at 480-620°C to form strengthening precipitates, achieving tensile strengths up to 1,100 MPa. Martensitic stainless steels like 410 undergo quenching and tempering cycles, with water quenching from 900-980°C to form hard martensite, then tempering at 200-300°C to balance strength and toughness. We use computer-controlled furnaces to ensure precise temperature control (±2°C) and uniform cooling rates, critical for consistent strength development across complex geometries. For duplex stainless steels, we apply controlled cooling to maintain the optimal ferrite-austenite balance (50-50%) that provides both strength and corrosion resistance. This post-forging heat treatment process unlocks the full strength potential of stainless steel, transforming forged blanks into high-performance components.

Stainless Steel Forging: Quality Inspection and Testing for Strength Validation

Comprehensive inspection and testing processes verify the strength and integrity of stainless steel forged components before they enter service. We perform 100% dimensional inspections using coordinate measuring machines, ensuring critical features meet design tolerances that affect assembly and stress distribution. Non-destructive testing includes ultrasonic inspection to detect internal defects and magnetic particle testing for surface cracks in ferritic grades. Mechanical testing is performed on sample components from each production batch, measuring tensile strength, yield strength, and elongation to ensure compliance with material specifications. For high-criticality applications, we conduct fatigue testing to verify performance under cyclic loading, ensuring stainless steel forged parts meet 10^7 cycle requirements. Microstructure analysis using optical microscopy confirms proper grain refinement and heat treatment response. This rigorous testing regime validates that the stainless steel forging processes have successfully produced components with the required high-strength properties for their intended application.