Stainless Steel Forging: Energy-Efficient Heating Systems for Reduced Carbon Footprint

Implementing energy-efficient heating technologies is a cornerstone of sustainable stainless steel forging, significantly reducing our carbon footprint while maintaining production quality. We’ve replaced traditional gas-fired furnaces with induction heating systems that convert 85% of energy input into useful heat, compared to just 40-50% efficiency in conventional systems. These induction systems target heat directly to the stainless steel billet, minimizing energy waste and reducing CO₂ emissions by 40% per ton of forged material. We’ve also installed heat recovery systems that capture waste heat from forging presses and furnace exhausts, repurposing it for facility heating and pre-heating incoming billets. Smart temperature controls maintain precise heating profiles, preventing over-energy consumption while ensuring optimal forging conditions. These energy-saving practices not only lower our environmental impact but also reduce operating costs, making sustainable stainless steel forging economically viable.

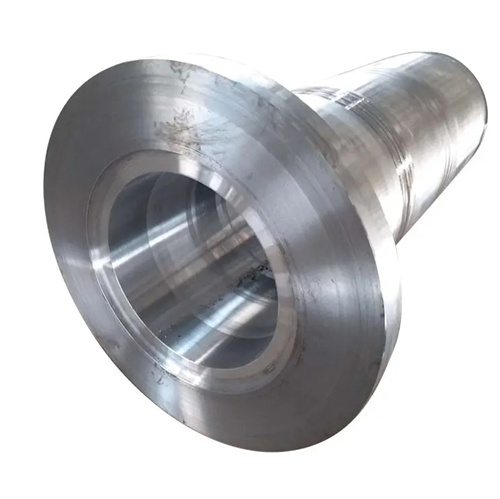

Stainless Steel Forging: Material Waste Reduction Through Precision Processes

Stainless steel forging inherently minimizes material waste, and our precision practices further enhance this sustainability advantage. The near-net-shape production of forging reduces material consumption by 40-60% compared to machining from solid stock, with typical scrap rates below 15% for most components. We optimize billet sizing using computer simulations that calculate exact material requirements for each part, eliminating excess material that would otherwise become waste. Our advanced die design ensures complete material utilization, with minimal flash that requires trimming. The stainless steel scrap generated during forging is fully recyclable, with 95% of it returned to our material suppliers for reprocessing into new billets. This closed-loop material system reduces the need for virgin raw materials and the energy required for primary steel production. By minimizing waste throughout the stainless steel forging process, we conserve natural resources while lowering disposal costs.

Stainless Steel Forging: Water Conservation and Recycling Systems

Water conservation is a key sustainable practice in our stainless steel forging operations, protecting this vital resource while maintaining production standards. We’ve implemented closed-loop water recycling systems for cooling applications, treating and reusing 95% of the water used in forging presses and heat treatment processes. These systems use advanced filtration and chemical treatment to maintain water quality, reducing freshwater intake by 70% compared to once-through cooling systems. We’ve replaced high-pressure water sprays with air-cooled systems where possible, further reducing consumption. For processes requiring water-based lubricants, we use biodegradable formulations that minimize environmental impact if any discharge occurs. Smart sensors monitor water usage in real-time, detecting leaks and optimizing flow rates to prevent waste. These water conservation practices ensure our stainless steel forging operations minimize their impact on local water resources.

Stainless Steel Forging: Renewable Energy Integration for Clean Production

Integrating renewable energy sources into our stainless steel forging operations reduces our reliance on fossil fuels and lowers greenhouse gas emissions. We’ve installed solar panel arrays that generate 30% of our facility’s electricity needs, powering lighting, ventilation, and auxiliary equipment used in forging processes. For higher energy demands, we purchase renewable energy certificates to offset the remaining electrical consumption, ensuring 100% of our energy comes from clean sources. We’ve also replaced diesel-powered material handling equipment with electric alternatives charged from our solar system, eliminating on-site emissions from forklifts and cranes. These renewable energy investments have reduced our carbon footprint by 25% annually, with ongoing plans to expand solar capacity to 50% of our needs. By combining renewable energy with energy-efficient processes, we’re moving toward carbon-neutral stainless steel forging production.

Stainless Steel Forging: Emission Control Technologies for Air Quality

Advanced emission control technologies ensure our stainless steel forging operations maintain high air quality standards while meeting sustainability goals. We’ve installed high-efficiency particulate filters on all furnace exhausts, capturing 99% of metal oxides and particulate matter generated during heating. For processes involving lubricants and coolants, we use low-VOC (volatile organic compound) formulations and vapor recovery systems that prevent harmful emissions from escaping into the atmosphere. Our facility uses a centralized dust collection system that captures airborne particles from forging, trimming, and finishing operations, preventing them from being released into the environment. We regularly monitor emissions to ensure compliance with environmental regulations, maintaining levels well below permissible limits. These emission control measures protect worker health while minimizing the environmental impact of our stainless steel forging processes.

Stainless Steel Forging: Extended Tool Life Practices for Resource Conservation

Maximizing tool life in stainless steel forging conserves resources by reducing the need for frequent die replacement and the associated material and energy costs. We use advanced die materials like powder metallurgy H13 steel that resist wear and thermal fatigue, extending tool life by 30-50% compared to conventional tool steels. Precision die maintenance programs include regular inspection, cleaning, and reconditioning that prevent premature failure and extend service intervals. We apply protective ceramic coatings to die surfaces that reduce friction and heat transfer, minimizing wear during forging cycles. Our predictive maintenance system uses sensor data to anticipate die wear, allowing for timely reconditioning before catastrophic failure occurs. By extending die life from 50,000 to 75,000 cycles for most components, we reduce the energy and materials required for die production, making our stainless steel forging operations more sustainable while reducing tooling costs.