Stainless Steel Forging: Structural Integrity for Critical Aerospace Components

Stainless steel forging provides the structural integrity essential for critical aerospace components where failure is not an option. By aligning metal grains through controlled deformation, we create components with exceptional strength-to-weight ratios that withstand the extreme forces of flight. For airframe structures, stainless steel forged parts like wing attachments and landing gear components 承受 (withstand) dynamic loads during takeoff, flight, and landing that would compromise cast alternatives. Our forged 17-4 PH stainless steel fasteners achieve tensile strengths up to 1,100 MPa while maintaining corrosion resistance, securing critical joints in both commercial and military aircraft. The fatigue resistance of stainless steel forging is particularly vital—components like engine mounts endure millions of stress cycles, and our forged parts demonstrate 30-50% longer fatigue life than machined alternatives. This structural reliability makes stainless steel forging indispensable for aerospace applications where safety and performance are paramount.

Stainless Steel Forging: High-Temperature Performance in Aerospace Propulsion

Aerospace propulsion systems demand components that maintain performance at extreme temperatures, and stainless steel forging delivers this critical capability. We produce forged components for jet engines and rocket propulsion systems using heat-resistant stainless steel alloys like 310 and 321 that retain strength at temperatures exceeding 1,000°C. These stainless steel forged parts include turbine disks, combustion chamber liners, and exhaust components that operate in harsh thermal environments. The forging process creates a dense microstructure that resists creep deformation under prolonged high heat, ensuring propulsion systems function reliably through thousands of flight hours. For military aircraft requiring high-thrust engines, our stainless steel forged components withstand rapid temperature fluctuations during combat maneuvers without cracking. This high-temperature performance ensures aerospace propulsion systems deliver consistent thrust while maintaining structural integrity, making stainless steel forging a cornerstone of aviation power systems.

Stainless Steel Forging: Corrosion Resistance for Aerospace and Defense Environments

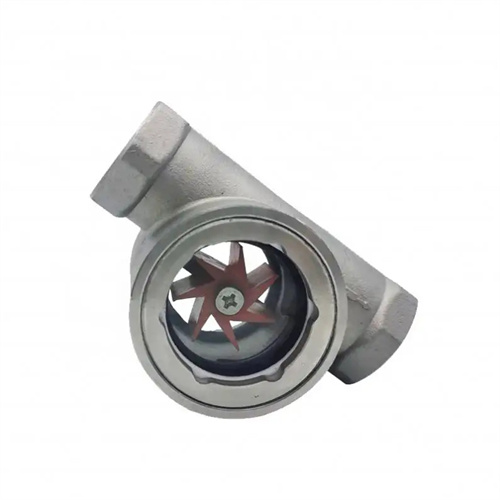

In aerospace and defense applications, stainless steel forging provides superior corrosion resistance that protects components from harsh operational environments. Aircraft face moisture, salt spray, and atmospheric contaminants during flight and ground operations, making corrosion resistance critical for longevity. We produce stainless steel forged components like hydraulic fittings and avionics housings using 316 stainless steel that resists saltwater corrosion—essential for naval aviation and coastal military bases. For defense equipment deployed in extreme environments, from desert sandstorms to arctic conditions, our forged stainless steel parts maintain performance without degradation. The smooth surface finish of stainless steel forging minimizes crevice corrosion, a critical advantage for aerospace components with tight tolerances. This corrosion resistance reduces maintenance requirements and extends service intervals, ensuring aerospace and defense systems remain mission-ready in any environment.

Stainless Steel Forging: Precision Manufacturing for Aerospace Tolerances

Aerospace and defense systems require exceptional precision, and stainless steel forging delivers the tight tolerances and dimensional stability needed for these applications. We achieve accuracies of ±0.003 inches for critical features in stainless steel forged components, ensuring proper fit in complex assemblies like flight control systems and weapons platforms. The controlled deformation process minimizes springback and residual stresses, ensuring parts maintain their dimensions through subsequent heat treatment and service. For aerospace instrumentation, our stainless steel forged housings provide precise mounting surfaces for sensitive sensors, maintaining calibration through vibration and temperature changes. In defense applications like missile guidance systems, the dimensional stability of stainless steel forging ensures components interact with micron-level precision, critical for targeting accuracy. This precision manufacturing capability makes stainless steel forging essential for aerospace and defense systems where even minor dimensional variations can affect performance.

Stainless Steel Forging: Material Versatility for Defense Equipment Diversity

Defense equipment encompasses diverse applications with varying requirements, and stainless steel forging offers the material versatility to meet this wide range of needs. We produce stainless steel forged components for ground vehicles, naval vessels, and aircraft using alloys tailored to specific operational demands. For armored vehicles, high-strength martensitic stainless steel forgings provide ballistic protection while maintaining structural lightness. Naval defense systems utilize duplex stainless steel forgings for propeller shafts and valve components that resist both corrosion and cavitation erosion. In infantry equipment, our stainless steel forged parts balance strength and weight for portable weapons systems and protective gear. The ability to forge various stainless steel grades—from austenitic to precipitation-hardening alloys—allows us to match material properties to defense requirements, whether that’s high strength, corrosion resistance, or magnetic permeability. This versatility makes stainless steel forging a go-to solution for diverse defense applications.

Stainless Steel Forging: Reliability and Traceability for Mission-Critical Systems

In aerospace and defense, reliability and traceability are non-negotiable, and stainless steel forging supports both through rigorous processes. Every stainless steel forged component we produce comes with complete material traceability, from raw material certification to final inspection, meeting strict aerospace standards like AS9100 and defense specifications. This traceability ensures full accountability for mission-critical components, enabling rapid identification and resolution of any issues. The consistency of stainless steel forging minimizes part-to-part variation, ensuring uniform performance across aircraft fleets or defense systems. For military applications requiring operational readiness, the reliability of stainless steel forged components reduces the risk of mission failure due to component malfunction. Our comprehensive testing protocols—including ultrasonic inspection, tensile testing, and fatigue analysis—verify every stainless steel forged part meets performance requirements. This commitment to reliability and traceability makes stainless steel forging indispensable for aerospace and defense systems where mission success depends on component performance.