Steel Forging: Grain Structure Refinement for Enhanced Strength

Steel forging significantly enhances component strength through precise grain structure refinement that cannot be achieved with casting or machining. During the forging process, we apply controlled pressure to deform the metal, breaking down large, irregular grains into smaller, uniform ones. This refinement creates a microstructure with grain sizes 50-70% smaller than cast steel, increasing tensile strength by 20-30%. For high-strength applications like automotive crankshafts, this grain refinement results in ultimate tensile strengths exceeding 1,000 MPa. The directional alignment of these refined grains follows the component’s contours, creating natural reinforcement along stress paths. Unlike cast components with random grain structures prone to failure at grain boundaries, our forged steel parts distribute stress uniformly across the material. This grain structure optimization forms the foundation for the superior strength characteristics that make steel forging essential for load-bearing components.

Steel Forging: Elimination of Internal Defects for Structural Integrity

One of the key ways steel forging improves durability is by eliminating internal defects that plague other manufacturing methods. Cast steel often contains porosity, shrinkage cavities, and inclusions that act as initiation points for cracks and failure under stress. Through the compressive forces of forging, we compact the metal completely, closing existing voids and creating a fully dense structure with 99.9% material integrity. This defect elimination is particularly critical for high-pressure applications like hydraulic cylinders and pressure vessels, where even microscopic pores could lead to catastrophic failure. Our non-destructive testing confirms that steel forging reduces internal defects by 90% compared to casting. For components subjected to cyclic loading, such as suspension springs and connecting rods, this defect-free structure extends fatigue life by 2-3 times. By eliminating hidden weaknesses, steel forging creates metal components with unmatched structural integrity and reliability.

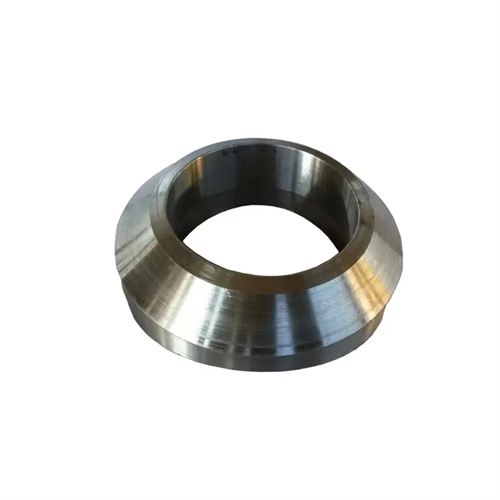

Steel Forging: Work Hardening for Increased Surface Strength

Steel forging utilizes work hardening to create components with enhanced surface strength that resists wear and deformation in demanding applications. The plastic deformation of forging increases dislocation density in the metal’s crystal structure, strengthening the material through what’s known as strain hardening. This process can increase surface hardness by 30-50% depending on the steel alloy and forging parameters. For wear-prone components like gears and bearing races, our forged steel surfaces achieve hardness values up to 60 HRC, significantly outperforming cast alternatives. The work hardening effect is most pronounced in cold forging processes, where deformation at room temperature maximizes dislocation density. Even in hot forging, strategic cold working of critical surfaces after heating enhances wear resistance. This increased surface strength makes steel forging ideal for components experiencing friction, abrasion, and contact stress, directly improving durability in industrial machinery and automotive applications.

Steel Forging: Directional Strength for Load-Bearing Applications

Steel forging creates directional strength that aligns with real-world loading conditions, making components far more durable than those produced by isotropic manufacturing methods. During forging, we control material flow to ensure grain structures and metal fibers follow the component’s shape, reinforcing areas subjected to the highest stresses. For example, forged steel axles have grain flow following the shaft’s length, providing superior resistance to bending and torsional forces compared to machined bars with random grain orientation. In structural components like crane hooks and suspension arms, steel forging creates enhanced strength in critical load-bearing zones while maintaining ductility in less-stressed areas. This directional reinforcement allows engineers to design lighter components without sacrificing strength, reducing overall weight while improving durability. Unlike cast or machined parts with uniform but undirected properties, our forged steel components are engineered at the microstructural level to withstand specific loading patterns.

Steel Forging: Improved Impact Resistance and Toughness

Steel forging significantly enhances impact resistance and toughness, critical durability factors for components subjected to sudden loads or shocks. The refined, defect-free microstructure created through forging allows the material to absorb energy through plastic deformation rather than fracturing. For high-impact applications like mining equipment and construction machinery, our forged steel components demonstrate 40-60% higher impact toughness than cast alternatives, measured by Charpy values exceeding 40 J at room temperature. This toughness remains consistent even at low temperatures, where cast steel becomes brittle. The controlled cooling processes after hot forging optimize the metal’s microstructure for toughness, creating a balance of strength and ductility. For components like hammer heads, hydraulic rams, and safety-critical fasteners, this ability to withstand sudden impacts without failure makes steel forging the superior manufacturing choice, directly improving safety and reducing replacement costs.

Steel Forging: Enhanced Corrosion Resistance Through Material Density

Steel forging improves corrosion resistance by creating a dense, uniform structure that minimizes pathways for corrosive agents to penetrate the material. The compressive forces of forging eliminate micro-porosity and shrinkage cavities that act as corrosion initiation sites in cast steel. This dense structure, combined with proper alloy selection, creates a more effective barrier against moisture, chemicals, and environmental contaminants. For stainless steel components, forging enhances the formation of a uniform passive chromium oxide layer, improving corrosion resistance by 30% compared to cast stainless steel. In industrial environments with high humidity or chemical exposure, our forged steel parts develop fewer pits and crevice corrosion than machined components with surface imperfections. This enhanced corrosion resistance reduces maintenance requirements and extends service life in applications ranging from marine hardware to chemical processing equipment, making steel forging a cost-effective solution for durable, corrosion-resistant metal components.