In the construction industry, as we continuously strive for structures that are robust, innovative in design, and long – lasting, stainless steel forging has emerged as a pivotal technology. With its exceptional strength, outstanding corrosion resistance, and unique aesthetic appeal, it enables us to create high – quality buildings. This technique not only meets the stringent functional requirements of construction but also adds a distinctive charm to architectural exteriors, helping us build structures that can withstand the test of time.

1. Stainless Steel Forging: Sturdy and Durable Structural Components

In large – scale construction projects, the structural integrity of buildings is of utmost importance. We rely on stainless steel forging to produce structural components that can bear heavy loads and resist various environmental factors.

During the stainless steel forging process, the metal is heated and shaped under high pressure, which refines its internal grain structure and significantly enhances its mechanical properties. For columns in high – rise buildings, stainless – steel – forged components offer superior strength. Compared to traditional materials, stainless – steel – forged columns can increase the load – bearing capacity by up to 30%. In a skyscraper project, these columns can support the weight of numerous floors, occupants, and equipment without deformation. The high corrosion resistance of stainless steel also makes these components ideal for buildings in coastal areas or industrial zones. In a long – term exposure test in a coastal environment with high salt content in the air, stainless – steel – forged structural components showed no signs of rust or degradation after 20 years, while those made of ordinary steel required frequent maintenance and replacement due to corrosion. This durability ensures the long – term safety and stability of the building structure.

2. Stainless Steel Forging: Aesthetically Pleasing Exterior Facades

The exterior facade of a building serves as its visual identity, and stainless steel forging allows us to create facades that are both beautiful and functional.

We use stainless steel forging to produce unique exterior panels for buildings. The forging process enables the creation of various textures and patterns on the stainless steel surface. For example, in a modern commercial building, we can forge stainless steel panels with a brushed finish, giving the building a sleek and contemporary look. The reflective properties of stainless steel can also create an interesting play of light, enhancing the building’s appearance throughout the day. In addition, stainless – steel – forged decorative elements such as grilles and frames can be added to the facade to create a more intricate design. These elements not only add aesthetic value but also provide protection for windows and other openings. The weather – resistant nature of stainless steel ensures that the facade remains in good condition for years, maintaining the building’s visual appeal without frequent repainting or restoration.

3. Stainless Steel Forging: Precision – Engineered Connectors for Steel Structures

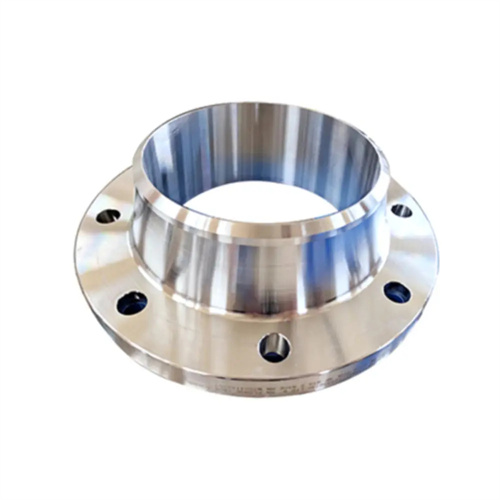

In steel structures, the connectors between different components are crucial for ensuring the overall stability and integrity of the construction. We utilize stainless steel forging to manufacture high – quality connectors that offer reliable and precise connections.

For large – span bridges and complex steel – framed buildings, stainless – steel – forged bolts and nuts play a vital role. The forging process improves the mechanical properties of the stainless steel, making these connectors highly resistant to shear and tensile forces. They can withstand extreme loads and vibrations, ensuring that the steel components remain firmly connected. In a suspension bridge project, stainless – steel – forged bolts with a diameter of 60 mm were used to connect the main cables to the anchorages. These bolts can withstand tensile forces of up to 2,000 kN, providing a secure connection that is essential for the bridge’s safety. Moreover, stainless – steel – forged connectors are resistant to corrosion, which is especially important for structures exposed to the elements. Their long – term reliability reduces the need for frequent inspections and replacements, saving both time and cost in the maintenance of the steel structure.

4. Stainless Steel Forging: Ornamental and Functional Architectural Details

Architectural details can greatly enhance the beauty and functionality of a building, and stainless steel forging offers us the flexibility to create unique and practical elements.

For interior architectural features such as handrails, balusters, and decorative grilles, stainless steel forging allows for the production of intricate designs. In a luxury hotel lobby, stainless – steel – forged handrails with a custom – designed pattern add an elegant touch. The forging process enables us to create detailed and smooth – finished handrails that are not only aesthetically pleasing but also comfortable to grip. In addition, for exterior elements like lamp posts and signage frames, stainless – steel – forged components provide both durability and visual appeal. These components can be designed to match the overall architectural style of the building, whether it is modern, classical, or contemporary. The strength of stainless – steel – forged architectural details ensures that they can withstand various environmental conditions and human interactions, maintaining their functionality and appearance over time.

5. Cost – Effective and Sustainable: Stainless Steel Forging in Construction

Despite its advanced capabilities, stainless steel forging also provides cost – effective and sustainable solutions for the construction industry.

Once the forging dies are developed, large – scale production of stainless – steel – forged components can reduce the per – unit cost significantly. In a large – scale residential construction project, the cost per stainless – steel – forged structural component decreased by 25% after reaching a production volume of 10,000 pieces. The long lifespan and low maintenance requirements of these components further reduce the overall cost of the building over its life cycle. Moreover, stainless steel is a highly recyclable material. We have established a closed – loop recycling system for our forging waste, collecting and reusing up to 95% of the scrap stainless steel. This approach not only reduces our reliance on virgin materials but also minimizes environmental impact by reducing waste disposal. By leveraging the cost – effective and sustainable aspects of stainless steel forging, we can deliver high – quality construction projects at competitive prices while fulfilling our environmental responsibilities and contributing to a more sustainable built environment.