In the dynamic landscape of the energy sector, alloy steel forging stands as an essential cornerstone, enabling the reliable operation of diverse energy – related systems. Whether it’s the intense heat of thermal power generation, the precise mechanisms of nuclear reactors, or the vast turbines harnessing wind energy, alloy steel forgings play a pivotal role. Their exceptional strength, resistance to extreme temperatures, and durability against fatigue and corrosion make them the material of choice for critical components that endure some of the harshest operating conditions. As we strive to meet the world’s growing energy demands, alloy steel forgings empower us to build robust, efficient, and sustainable energy infrastructure.

1. Alloy Steel Forging in Thermal Power Generation

In thermal power plants, where heat is converted into electricity, alloy steel forgings are integral to the construction of key equipment. High – pressure steam turbines, the workhorses of thermal power generation, rely on alloy steel forgings for their rotors, shafts, and turbine discs. These components operate under intense mechanical stresses, high rotational speeds, and temperatures often exceeding 500°C. Alloy steels used in turbine manufacturing typically contain elements such as chromium, molybdenum, and vanadium. Chromium enhances corrosion resistance, safeguarding the components from the corrosive effects of steam and combustion by – products. Molybdenum improves the steel’s resistance to creep deformation under high – temperature and high – stress conditions, while vanadium refines the grain structure, boosting overall strength and toughness.

The forging process for turbine components is a highly specialized operation. The alloy steel billet is first heated to an optimal temperature range, carefully monitored to ensure uniform heating. Through a series of precise forging operations, the metal is shaped, aligning the grain structure to maximize strength along the direction of stress. Subsequent heat treatment processes, including quenching and tempering, further optimize the mechanical properties, ensuring the components can withstand continuous operation over extended periods and contribute to the efficient generation of electricity.

2. Alloy Steel Forging in Nuclear Power Systems

Nuclear power plants demand the utmost in safety and reliability, and alloy steel forgings are crucial in meeting these stringent requirements. Reactor pressure vessels, which house the nuclear core and contain radioactive materials under high pressure and temperature, are often fabricated using large – scale alloy steel forgings. The alloy steels selected for these vessels are carefully engineered to possess excellent fracture toughness, resistance to radiation – induced embrittlement, and high – temperature strength. Elements like nickel and manganese are added to enhance the steel’s toughness and corrosion resistance, while boron may be included to absorb excess neutrons and help control the nuclear reaction.

The forging of reactor pressure vessels is a complex and highly regulated process. Specialized forging techniques, such as ring rolling and radial forging, are employed to achieve the required dimensions and mechanical properties. Rigorous quality control measures, including non – destructive testing methods like ultrasonic and radiographic testing, are implemented throughout the manufacturing process to ensure the vessels are free from defects and can safely contain nuclear reactions for decades, providing a stable source of low – carbon energy.

3. Alloy Steel Forging in Wind Energy Turbines

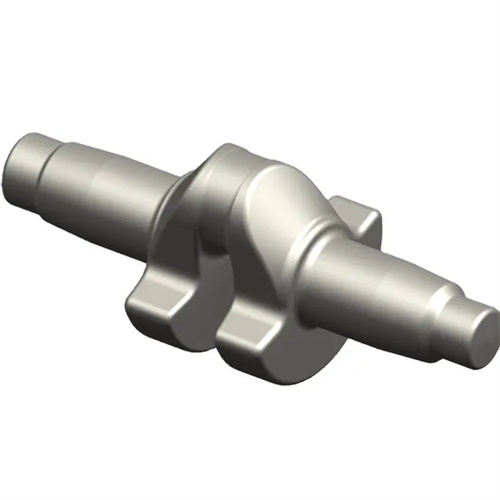

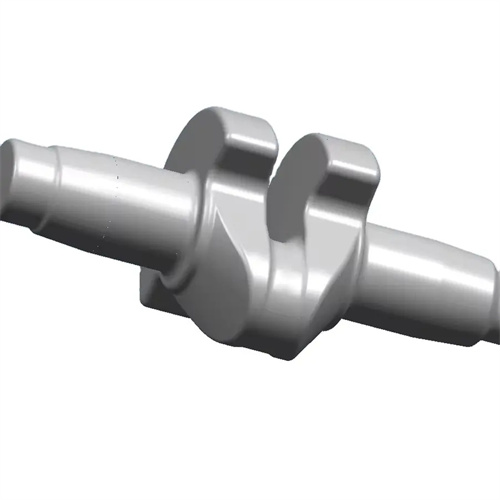

In the rapidly expanding field of wind energy, alloy steel forgings are essential for the construction of wind turbines. The main shafts of wind turbines, which transfer the rotational energy from the blades to the generator, are subjected to significant bending and torsional loads. These shafts are typically forged from high – strength alloy steel, providing the necessary durability to withstand the constant and variable forces exerted by the wind. Alloy steels with elements like chromium and molybdenum are commonly used to enhance the shaft’s resistance to fatigue and wear, ensuring a long service life even in harsh outdoor environments.

Other critical components of wind turbines, such as the hub and gearbox parts, also rely on alloy steel forgings. The hub, which connects the blades to the main shaft, must be strong enough to withstand the aerodynamic forces acting on the blades during operation. Alloy steel forgings are used to fabricate the hub, offering the required strength and rigidity. Gearbox components, which increase the rotational speed of the generator, are made from alloy steel forgings to ensure high precision and durability, enabling efficient power transmission and contributing to the overall reliability of wind energy generation.

4. Alloy Steel Forging in Oil and Gas Extraction

The oil and gas industry operates in some of the most challenging environments, both onshore and offshore, and alloy steel forgings are vital for its equipment. Drill pipes, used to drill deep into the earth to extract oil and gas, are made from high – strength alloy steel forgings. These pipes must endure high pressures, torsional stresses, and abrasive forces as they penetrate through various rock formations. Alloy steels with high levels of chromium, molybdenum, and vanadium are utilized to enhance the drill pipes’ resistance to corrosion, wear, and fatigue.

In offshore oil and gas platforms, components such as risers, which connect the wellhead on the seabed to the platform, and structural supports are fabricated using alloy steel forgings. These components need to be extremely strong and corrosion – resistant to withstand the harsh marine environment, including saltwater corrosion, strong currents, and high waves. The forging process for these offshore components involves strict quality control to ensure they can endure the demanding operating conditions and enable the safe and efficient extraction of valuable energy resources.

5. Advancements and Future Prospects of Alloy Steel Forging in the Energy Sector

As the energy sector continues to evolve towards greater sustainability and efficiency, alloy steel forging technology is also advancing. Researchers are exploring new alloy compositions to further enhance the material’s properties. For instance, the incorporation of nano – sized alloying elements shows promise in improving the strength – to – weight ratio of alloy steel, enabling the production of lighter yet stronger components for energy equipment. This could lead to reduced material costs, lower energy consumption during manufacturing, and improved overall efficiency of energy systems.

Advanced forging techniques, such as precision forging and near – net – shape forging, are becoming more prevalent. These techniques not only reduce material waste and production costs but also improve the dimensional accuracy and performance of the forged components. In the future, as the energy industry increasingly focuses on renewable energy sources and smart grid technologies, alloy steel forgings will need to adapt to new requirements. By investing in research and development and leveraging emerging technologies, we can ensure that alloy steel forging remains at the forefront of energy equipment manufacturing, driving the development of a more sustainable and reliable energy future.