In the expansive realm of general machinery, where reliability, durability, and efficiency are paramount, alloy steel forging emerges as an indispensable cornerstone. From the gears that silently transfer power to the shafts that endure heavy loads, alloy steel forgings are the unsung heroes enabling countless machines to function seamlessly across diverse industries. Their unique combination of high strength, exceptional wear resistance, and remarkable toughness makes them the ideal choice for components subjected to rigorous mechanical stresses, abrasive environments, and continuous operation. As we delve into the applications of alloy steel forgings in general machinery, it becomes evident how they underpin the performance, longevity, and productivity of these essential mechanical systems.

1. Alloy Steel Forging in Mechanical Transmission Components

In the heart of many general machinery systems lie mechanical transmission components, and alloy steel forgings play a crucial role in their construction. Gears, the workhorses of power transmission, are often forged from high – quality alloy steel. These components are subjected to high contact stresses, friction, and impact forces during operation, demanding materials with superior strength and wear resistance. Alloy steels used for gear manufacturing typically contain elements such as chromium, nickel, and molybdenum. Chromium enhances the surface hardness, providing excellent resistance to abrasion and pitting, while nickel improves the toughness, allowing the gears to withstand sudden shocks without cracking. Molybdenum, on the other hand, boosts the fatigue strength, enabling the gears to endure millions of cycles of rotation without failure.

Shafts, which transmit torque and support rotating components, also rely heavily on alloy steel forgings. These shafts are exposed to bending, torsional, and shear stresses, especially in applications with varying loads and speeds. The forging process aligns the grain structure of the alloy steel along the length of the shaft, maximizing its strength and fatigue resistance. Through subsequent heat treatment processes, such as quenching and tempering, the mechanical properties of the shafts are optimized, ensuring they can safely carry heavy loads and maintain their integrity over extended periods of operation.

2. Alloy Steel Forging in Hydraulic and Pneumatic Systems

Hydraulic and pneumatic systems are integral to the operation of numerous general machinery applications, and alloy steel forgings are essential for their key components. Cylinders, the power – generating elements of these systems, are often fabricated from alloy steel forgings. These cylinders need to withstand high internal pressures and mechanical forces, requiring materials with exceptional strength and pressure – resistance. The alloy steel used for cylinders offers excellent formability, allowing for the production of components with precise internal diameters and wall thicknesses, ensuring smooth and efficient operation.

Pistons, which move within the cylinders, are also commonly made from alloy steel forgings. Subjected to high frictional forces and rapid changes in pressure, pistons demand materials with high wear resistance and durability. The forging process imparts the necessary strength and hardness to the pistons, enabling them to operate smoothly and efficiently, reducing energy losses and extending the service life of the hydraulic or pneumatic system. Additionally, valves, fittings, and other critical components in these systems often rely on alloy steel forgings to ensure reliable performance under demanding operating conditions.

3. Alloy Steel Forging in Machine Tool Components

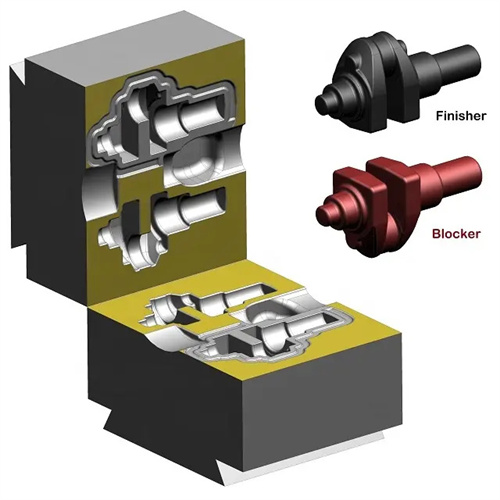

Machine tools are the backbone of manufacturing, and alloy steel forgings contribute significantly to their performance and precision. Spindles, the rotating components of machine tools that hold and drive cutting tools, are typically forged from high – quality alloy steel. These spindles need to maintain high rotational accuracy and withstand heavy cutting forces, making materials with excellent strength, stiffness, and fatigue resistance essential. The forging process for spindles ensures a uniform grain structure, enhancing their mechanical properties and enabling them to operate smoothly at high speeds.

Tool holders, which secure the cutting tools to the spindle, also benefit from alloy steel forgings. These components must provide a secure and rigid connection to ensure accurate machining. The high – strength and durability of alloy steel forgings ensure that tool holders can withstand the vibrations and forces generated during cutting operations, maintaining the precision and quality of the machined parts. Moreover, components such as guide rails and lead screws in machine tools, which are crucial for linear motion and positioning, often rely on alloy steel forgings for their strength and wear – resistance.

4. Alloy Steel Forging in Agricultural Machinery

Agricultural machinery operates in harsh outdoor environments, facing abrasive soil, heavy loads, and varying weather conditions. Alloy steel forgings are widely used in the construction of agricultural equipment to ensure durability and reliability. Tractor axles, which support the weight of the tractor and transmit power to the wheels, are forged from high – strength alloy steel. These axles need to withstand the stresses of uneven terrain and heavy loads, and the properties of alloy steel forgings provide the necessary strength and toughness.

In addition, components such as plowshares, harrow tines, and combine harvester blades are often made from alloy steel forgings. These parts are in direct contact with the soil and crops, requiring materials with excellent wear resistance and impact strength. The forging process enhances the hardness and durability of these components, enabling them to cut through tough soil and crop residues efficiently, reducing maintenance requirements and increasing the productivity of agricultural operations.

5. Advancements and Future Prospects of Alloy Steel Forging in General Machinery

As technology continues to advance, the field of general machinery is constantly evolving, and alloy steel forging is keeping pace with these changes. New alloy compositions are being developed to further enhance the properties of alloy steel forgings. For example, the incorporation of nano – sized alloying elements is being explored to improve the strength – to – weight ratio, enabling the production of lighter yet stronger components. This could lead to more energy – efficient machinery, reducing operating costs and environmental impact.

Advanced forging techniques, such as precision forging and near – net – shape forging, are becoming more prevalent. These techniques not only reduce material waste and production costs but also improve the dimensional accuracy and surface finish of the forged components. In the future, as the demand for more intelligent, automated, and sustainable general machinery grows, alloy steel forgings will need to adapt to new requirements. By investing in research and development and leveraging emerging technologies, we can ensure that alloy steel forging remains at the forefront of general machinery manufacturing, enabling the creation of more innovative, reliable, and high – performance mechanical systems.