In the vast and diverse field of general machinery, where components are exposed to a wide range of operating conditions, from corrosive environments to heavy mechanical loads, stainless steel forging has emerged as a key manufacturing technique. As we strive to create reliable, durable, and efficient machinery, stainless steel forgings offer a unique combination of properties that meet the demanding requirements of various applications. Their exceptional corrosion resistance, high strength, and good formability enable us to produce components that can withstand harsh conditions, ensuring the smooth operation and extended lifespan of general machinery. Whether it’s in mechanical transmission systems, hydraulic and pneumatic components, or machine tool parts, stainless steel forgings play an indispensable role in enhancing the overall performance of general machinery.

1. Stainless Steel Forging in Mechanical Transmission Components

Mechanical transmission systems are the backbone of many general machinery applications, and stainless steel forgings are widely used in their key components. Gears, which are essential for power transfer and speed reduction, often benefit from stainless steel forging. Forged stainless steel gears possess excellent wear resistance and fatigue strength, allowing them to withstand the high – stress and high – speed conditions typical of transmission systems. The forging process refines the grain structure of the steel, enhancing its mechanical properties and ensuring a longer service life. In food processing machinery, for example, where gears are exposed to moisture and cleaning agents, stainless steel – forged gears resist corrosion, preventing contamination and ensuring the hygiene and safety of the production process.

Shafts, another critical part of mechanical transmission, also see significant advantages with stainless steel forging. Forged stainless steel shafts can withstand heavy loads and torque, while their corrosion – resistant nature protects them from environmental factors. In marine – based general machinery, such as shipboard winches and propeller shafts, stainless steel forgings prevent rusting caused by saltwater exposure, maintaining the integrity of the transmission system and reducing maintenance requirements. The high strength and durability of these forged shafts ensure reliable power transmission, even in the most challenging operating environments.

2. Stainless Steel Forging in Hydraulic and Pneumatic Systems

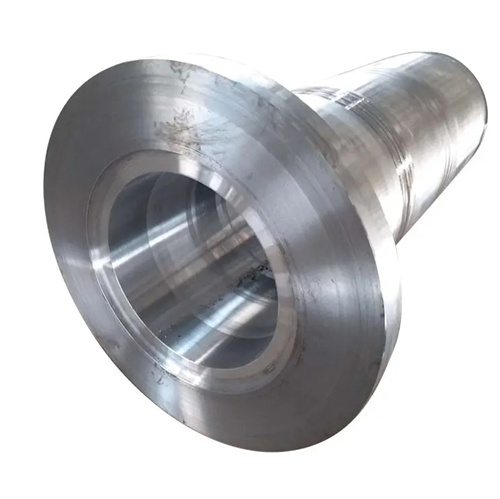

Hydraulic and pneumatic systems rely on components that can withstand high pressures and resist corrosion, making stainless steel forgings an ideal choice. Cylinders, a central component in these systems, can be manufactured using stainless steel forging. Forged stainless steel cylinders offer superior strength and corrosion resistance, ensuring they can handle high – pressure fluids without deformation or leakage. In construction equipment, such as hydraulic excavators and cranes, these cylinders maintain their performance even when exposed to dust, dirt, and moisture, providing consistent and reliable operation.

Pistons, valves, and fittings in hydraulic and pneumatic systems also benefit from stainless steel forging. Forged stainless steel pistons have a precise fit within cylinders, reducing friction and improving the overall efficiency of the system. Valves and fittings, with their corrosion – resistant properties, prevent the build – up of rust and debris, ensuring smooth fluid flow and preventing system failures. In chemical processing plants, where hydraulic and pneumatic systems may come into contact with corrosive chemicals, stainless steel forgings provide the necessary protection, safeguarding the integrity of the systems and minimizing downtime.

3. Stainless Steel Forging in Machine Tool Components

Machine tools require components that offer high precision, strength, and durability, and stainless steel forgings meet these demands effectively. Spindles, which are the rotating heart of machine tools, can be made from stainless steel forgings. Forged stainless steel spindles have excellent dimensional stability and resistance to wear, enabling them to maintain high – speed rotation with minimal vibration. This precision is crucial for achieving accurate machining results in applications such as CNC machining centers and lathes.

Tool holders and fixtures in machine tools also benefit from stainless steel forging. Forged stainless steel tool holders provide a secure and rigid connection for cutting tools, ensuring precise positioning during machining operations. Their corrosion – resistant property protects them from the coolant and lubricants used in machining, preventing rust and maintaining the accuracy of the tool – holding system. Fixtures, made from stainless steel forgings, can withstand the clamping forces and vibrations during machining, providing a stable platform for workpieces and ensuring the quality of the finished products.

4. Stainless Steel Forging in Agricultural Machinery

Agricultural machinery operates in harsh outdoor environments, facing challenges such as soil abrasion, moisture, and exposure to fertilizers and pesticides. Stainless steel forgings are increasingly being used in agricultural equipment to enhance durability and performance. Tractor frames, which bear the weight of the tractor and its attachments, can incorporate stainless steel forgings for critical components. The corrosion – resistant property of stainless steel protects the frame from rusting caused by moisture and chemicals in the soil, extending the lifespan of the tractor.

Components such as plowshares, harrow tines, and harvesting blades in agricultural machinery also benefit from stainless steel forging. Forged stainless steel plowshares are more resistant to wear and corrosion, allowing them to cut through tough soil more efficiently. Harrow tines and harvesting blades, with their high strength and durability, can withstand the continuous impact and friction during operation, reducing the need for frequent replacements. In addition, stainless steel forgings used in the hydraulic systems of agricultural machinery ensure reliable operation, even in dirty and wet conditions.

5. Advancements and Future Prospects of Stainless Steel Forging in General Machinery

The future of stainless steel forging in general machinery is filled with promise, driven by continuous advancements in materials science and forging technology. New stainless steel alloys with enhanced properties, such as improved strength – to – weight ratios, better resistance to high – temperature corrosion, and increased resistance to stress corrosion cracking, are being developed. These advanced alloys, when combined with innovative forging techniques like precision forging, near – net – shape forging, and 3D forging, will enable the production of more efficient, lightweight, and complex – shaped components for general machinery.

Furthermore, the integration of digital technologies, such as computer – aided design (CAD), computer – aided manufacturing (CAM), and simulation software, into the stainless steel forging process will enhance design optimization, quality control, and production efficiency. As the general machinery industry continues to focus on automation, energy efficiency, and sustainability, stainless steel forgings will play an increasingly important role. They will contribute to the development of more reliable, high – performance, and environmentally friendly general machinery, meeting the growing demands of various industries and driving the continuous evolution of the manufacturing sector.