In the broad and diverse field of general machinery, where components are required to endure a wide range of operating conditions, from heavy loads to high – speed rotations, steel forging has emerged as an indispensable manufacturing technique. As we strive to create machinery that is reliable, efficient, and long – lasting, steel forgings offer us the solution to meet these demanding requirements. Through the forging process, we can transform steel into components with optimized mechanical properties, precise dimensions, and enhanced durability. Whether it is in mechanical transmission systems, hydraulic and pneumatic equipment, or machine tools, steel forgings play a crucial role in enhancing the performance, reliability, and lifespan of general machinery.

1. Steel Forging in Mechanical Transmission Components

Mechanical transmission systems are the core of many general machinery applications, and steel forgings are widely used in their key components. Gears, which are responsible for power transfer and speed adjustment, often benefit significantly from steel forging. By using high – quality steel alloys and subjecting them to the forging process, we can produce gears with a refined grain structure, resulting in improved strength, wear resistance, and fatigue life. The forging process aligns the grain flow of the steel along the tooth profile of the gears, enhancing their ability to withstand heavy loads and high – speed rotations. For example, in industrial gearboxes, steel – forged gears can operate smoothly under high – torque conditions, reducing the risk of tooth breakage and ensuring the efficient transmission of power.

Shafts, another vital part of mechanical transmission systems, also rely on steel forging. Steel – forged shafts offer excellent dimensional stability and can withstand the bending and torsional stresses generated during operation. The forging process improves the internal structure of the steel, eliminating defects and enhancing its mechanical properties. In conveyor systems, steel – forged shafts can support the weight of the conveyor belt and the transported materials while maintaining high rotational accuracy, ensuring the smooth operation of the entire system.

2. Steel Forging in Hydraulic and Pneumatic Systems

Hydraulic and pneumatic systems require components that can withstand high pressures and ensure reliable performance, and steel forgings are well – suited for this purpose. Cylinders, a key component in these systems, are often manufactured using steel forging. Steel – forged cylinders offer high strength and durability, allowing them to withstand the internal pressures generated by hydraulic or pneumatic fluids. The forging process ensures the uniformity of the cylinder’s wall thickness and dimensional accuracy, reducing the risk of leakage and improving the overall efficiency of the system. In construction equipment, such as hydraulic excavators, steel – forged cylinders can provide the necessary force for lifting and moving heavy objects, ensuring the smooth operation of the machinery.

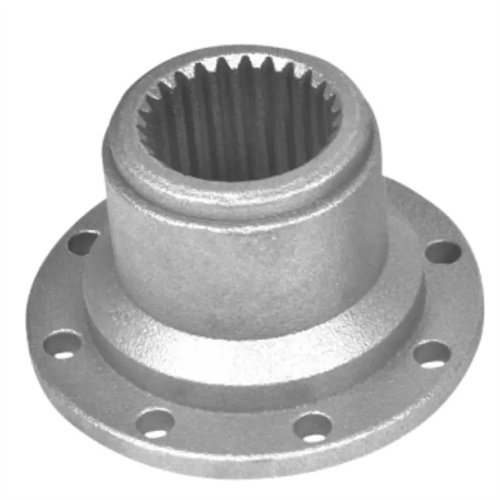

Pistons, valves, and fittings in hydraulic and pneumatic systems also benefit from steel forging. Steel – forged pistons have a precise fit within the cylinders, reducing friction and improving the system’s performance. Valves, made from steel forgings, can withstand high – pressure fluid flow and provide reliable control over the system. Fittings, such as couplings and connectors, forged from steel, offer strong and leak – proof connections, ensuring the integrity of the hydraulic and pneumatic circuits. The use of steel forgings in these components enhances the reliability and lifespan of hydraulic and pneumatic systems, reducing maintenance costs and downtime.

3. Steel Forging in Machine Tool Components

Machine tools demand components that offer high precision, strength, and rigidity, and steel forgings meet these requirements effectively. Spindles, which are the rotating heart of machine tools, are often made from steel forgings. Steel – forged spindles have excellent dimensional accuracy and can maintain high – speed rotation with minimal vibration. The forging process improves the material’s internal structure, enhancing its hardness and wear resistance. In CNC machining centers, steel – forged spindles can ensure the accuracy of cutting operations, enabling the production of high – precision parts.

Tool holders and guide rails in machine tools also benefit from steel forging. Steel – forged tool holders provide a secure and rigid connection for cutting tools, ensuring precise positioning during machining. Their high strength and durability prevent deformation under the cutting forces, maintaining the accuracy of the machining process. Guide rails, made from steel forgings, offer smooth and accurate movement of the machine’s axes. The forging process can produce guide rails with precise surface finishes and dimensional tolerances, ensuring the high – precision operation of machine tools and the quality of the manufactured parts.

4. Steel Forging in Agricultural Machinery

Agricultural machinery operates in harsh outdoor environments, facing challenges such as heavy loads, abrasive materials, and varying weather conditions. Steel forgings are increasingly being used in agricultural equipment to enhance its durability and performance. Tractor frames, which bear the weight of the tractor and its attachments, often incorporate steel – forged components. The high strength of steel forgings ensures the structural integrity of the tractor frames, allowing them to withstand the stresses generated during plowing, harvesting, and other agricultural operations.

Components such as plowshares, harrow tines, and harvesting blades in agricultural machinery also benefit from steel forging. Steel – forged plowshares are more resistant to wear and can cut through tough soil more efficiently. Harrow tines, made from steel forgings, can break up clods and prepare the soil effectively, even in hard – packed fields. Harvesting blades, forged from steel, maintain their sharpness and strength during the harvesting process, improving the efficiency of crop collection. The use of steel forgings in agricultural machinery reduces the frequency of component replacement, increases productivity, and lowers maintenance costs for farmers.

5. Advancements and Future Prospects of Steel Forging in General Machinery

The future of steel forging in general machinery is promising, with continuous advancements in materials science and forging technology. New steel alloys with enhanced properties, such as higher strength – to – weight ratios, better corrosion resistance, and improved fatigue performance, are being developed. These advanced alloys, when combined with innovative forging techniques like precision forging, near – net – shape forging, and isothermal forging, will enable the production of more efficient, lightweight, and reliable components for general machinery.

Moreover, the integration of digital technologies, such as computer – aided design (CAD), computer – aided manufacturing (CAM), and simulation software, into the steel forging process is revolutionizing the manufacturing industry. These technologies allow for more precise design, optimization of forging processes, and quality control, reducing production costs and improving the overall efficiency of the manufacturing process. As the general machinery industry continues to evolve towards automation, intelligence, and sustainability, steel forgings will play an even more significant role in driving innovation and meeting the growing demands of various industries.