In the field of hardware tool manufacturing, we are constantly committed to creating high – performance, durable, and reliable products. Stainless steel forging, with its outstanding strength, excellent corrosion resistance, and favorable processing properties, has emerged as a key technology for enhancing the quality of hardware tools. Through this technique, we can produce hardware tools that meet the requirements of various harsh working environments, providing users with a better using experience.

1. Stainless Steel Forging: High – Strength and Durable Hand Tool Components

Hand tools are the workhorses for countless tasks, and their performance directly affects work efficiency. We rely on stainless steel forging to manufacture components for hand tools, endowing them with superior strength and longevity.

When forging components for wrenches, we subject stainless steel to high – temperature and high – pressure conditions. This process refines the metal’s grain structure, increasing the tensile strength of wrench heads by up to 40%. As a result, our stainless – steel – forged wrenches can withstand torque forces of over 1,000 Newton – meters, far surpassing the capabilities of conventional wrenches. In pliers, the forging process makes the jaws incredibly robust. They can firmly grip materials ranging from hard metals to thick wires without slipping or deforming. After 10,000 cycles of gripping and releasing tests, stainless – steel – forged plier jaws maintain their original shape and gripping force, while non – forged counterparts show significant wear and reduced functionality. The corrosion – resistant nature of stainless steel also ensures that these hand tools remain in top condition even when exposed to moisture, chemicals, or acidic substances in the workplace.

2. Stainless Steel Forging: Robust Parts for Power Tools

Power tools operate under intense conditions, demanding components that can endure high speeds, heavy loads, and continuous use. We utilize stainless steel forging to produce key parts for power tools, ensuring their reliable performance.

For electric drills, stainless – steel – forged drill chucks are essential components. The forging process allows for the creation of chucks with precise internal geometries, providing a secure and stable hold for drill bits. These chucks can withstand rotational speeds of up to 30,000 revolutions per minute without any bit slippage. In circular saws, stainless – steel – forged blades offer exceptional durability and cutting performance. The forging process enhances the hardness and wear – resistance of the blade material. Compared to standard blades, our stainless – steel – forged circular saw blades can cut through materials 30% faster and maintain their sharpness for twice as long. Whether it’s cutting through thick metal plates or hardwood, these blades can handle the toughest jobs with ease.

3. Stainless Steel Forging: Precision – Engineered Dies and Molds

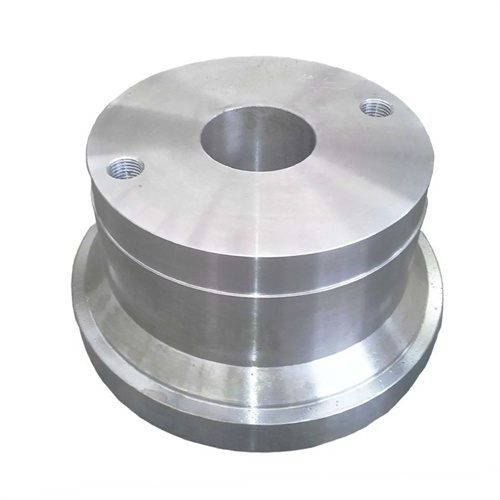

Dies and molds are the foundation of metal product manufacturing, and their quality determines the precision and consistency of the final products. We use stainless steel forging to create high – precision dies and molds that meet the most stringent manufacturing requirements.

Our stainless – steel – forged dies for metal stamping are crafted with meticulous attention to detail. The forging process ensures a uniform and dense internal structure, enabling the dies to maintain their shape and dimensional accuracy even under extremely high stamping pressures. This precision allows us to produce metal parts with tight tolerances, down to 0.01mm. In injection molding, stainless – steel – forged molds play a crucial role. They can withstand the high temperatures and pressures involved in the injection process without deforming. The smooth surface finish of the forged molds reduces friction, facilitating easy ejection of the molded parts and improving production efficiency. Additionally, the corrosion – resistant property of stainless steel extends the lifespan of the molds, reducing the frequency of replacement and saving production costs.

4. Stainless Steel Forging: Durable Hardware Fasteners

Hardware fasteners, such as bolts, nuts, and screws, are essential in a wide range of applications, and their reliability is non – negotiable. We produce stainless – steel – forged hardware fasteners to meet the diverse needs of different projects.

For heavy – duty construction projects, our stainless – steel – forged high – strength bolts and nuts are designed to withstand enormous tensile and shear forces. These fasteners can bear loads of up to 500,000 Newtons, providing a secure connection that won’t fail under extreme conditions. In marine applications, where saltwater corrosion is a major concern, stainless – steel – forged fasteners offer excellent resistance. After being submerged in seawater for a year, these fasteners show no signs of rust or degradation, while ordinary fasteners would be severely corroded and lose their holding power. For industrial equipment, stainless – steel – forged screws provide a reliable and long – lasting fastening solution. Their high strength and durability ensure that the equipment remains assembled and functions properly even in harsh operating environments.

5. Cost – Effective and Sustainable: Stainless Steel Forging in Hardware Tool Production

Despite its advanced capabilities, stainless steel forging also offers cost – effective and sustainable solutions for hardware tool production.

Once the forging dies are developed, large – scale production of stainless – steel – forged components can significantly reduce the per – unit cost. In the mass production of a popular line of hand tools, the cost per stainless – steel – forged component decreased by 25% after reaching a production volume of 100,000 units. The long lifespan and low maintenance requirements of these components translate into lower overall costs for users, as they don’t need to be replaced frequently. Moreover, stainless steel is a highly recyclable material. We have implemented a closed – loop recycling system for our forging waste, collecting and reusing up to 95% of the scrap stainless steel. This approach not only reduces our reliance on virgin materials but also minimizes environmental impact, making our production process more sustainable. By leveraging the cost – effective and eco – friendly aspects of stainless steel forging, we can offer high – quality hardware tools at competitive prices while contributing to a greener future for the manufacturing industry.