In the bustling world of rail transportation, where efficiency, safety, and speed are paramount, aluminum forging has emerged as a transformative technology. As we strive to build faster, more reliable, and environmentally friendly rail systems, aluminum forgings have become an integral part of our engineering toolkit. Their exceptional combination of lightweight, high strength, corrosion resistance, and formability makes them ideal for a wide range of applications in rail vehicles and infrastructure. From reducing the overall weight of trains to enhancing the durability of critical components, aluminum forgings are revolutionizing the way we design and operate rail transportation systems.

1. Aluminum Forging in Train Body Structures

The body structure of a train is one of the most critical components, and aluminum forgings play a significant role in its construction. By using aluminum alloy forgings for the body framework, we can achieve a substantial reduction in the vehicle’s weight without sacrificing strength. This lightweight design not only improves the energy efficiency of the train by reducing the power required for acceleration and deceleration but also enables higher speeds and smoother rides.

Aluminum forgings are used to fabricate various parts of the train body, such as side panels, roof sections, and floor beams. The forging process ensures that the aluminum alloy has a uniform grain structure, enhancing its mechanical properties and making it more resistant to fatigue and impact. For example, in high – speed trains, the use of aluminum forgings for the body structure helps to minimize aerodynamic drag and noise, providing a more comfortable and efficient travel experience for passengers. Additionally, the corrosion – resistant properties of aluminum forgings protect the train body from the damaging effects of moisture, salt, and other environmental factors, extending the lifespan of the vehicle.

2. Aluminum Forging in Train Bogie Components

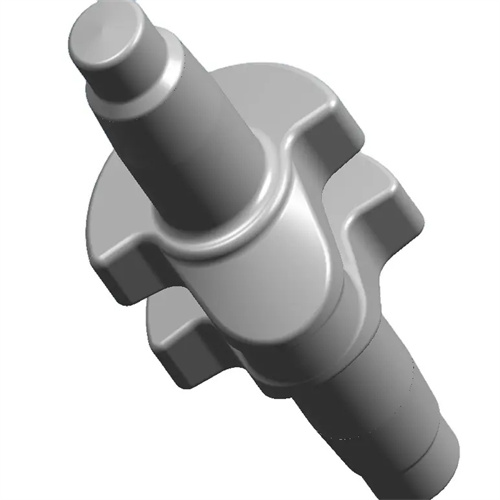

Bogies, also known as truck assemblies, are the undercarriage systems of trains that provide support, guidance, and stability. Many components of bogies, including frames, axles, and suspension parts, can benefit from the use of aluminum forgings. Aluminum alloy forgings offer a high strength – to – weight ratio, which is crucial for reducing the unsprung mass of the bogie. A lower unsprung mass results in better ride quality, reduced wear on the tracks, and improved traction.

The frames of bogies made from aluminum forgings are designed to withstand the significant lateral and vertical forces generated during train operation. The forging process allows for the creation of complex geometries that optimize the strength and stiffness of the frame while minimizing weight. Axles and suspension components forged from aluminum alloys also provide excellent fatigue resistance, ensuring reliable performance over long periods of use. By using aluminum forgings in bogie components, we can enhance the overall performance and reliability of the train, reducing maintenance costs and improving the safety of passengers and cargo.

3. Aluminum Forging in Rail Vehicle Interior Components

In addition to the structural components, aluminum forgings are also widely used in the interior of rail vehicles. From seat frames and armrests to luggage racks and decorative panels, aluminum alloy forgings offer a combination of strength, durability, and aesthetic appeal. The lightweight nature of aluminum forgings makes them ideal for interior applications, as it helps to further reduce the overall weight of the train without compromising on the comfort and functionality of the passenger compartment.

Aluminum forgings can be easily formed into various shapes and sizes, allowing for the creation of customized interior components that meet the specific requirements of different rail vehicle designs. The corrosion – resistant properties of aluminum also ensure that the interior components remain in good condition over time, even in the presence of moisture and cleaning chemicals. Moreover, the use of aluminum forgings in interior components can contribute to the overall sustainability of the rail vehicle, as aluminum is a highly recyclable material.

4. Aluminum Forging in Rail Transportation Braking Systems

Braking systems are vital for the safe operation of trains, and aluminum forgings play an important role in their construction. Brake discs, which are a key component of modern braking systems, can be made from aluminum alloy forgings. These discs offer several advantages over traditional cast iron discs, including lower weight, better heat dissipation, and improved corrosion resistance.

The lightweight nature of aluminum brake discs reduces the rotational inertia of the wheels, allowing for faster braking response times and more efficient energy recovery during regenerative braking. The excellent heat – dissipating properties of aluminum alloys help to prevent brake fade, ensuring consistent braking performance even under heavy loads and high – speed conditions. Additionally, the corrosion – resistant properties of aluminum forgings protect the brake discs from rust and wear, extending their service life and reducing maintenance requirements. By using aluminum forgings in braking systems, we can enhance the safety and reliability of rail transportation while also improving its energy efficiency.

5. Advancements and Future Prospects of Aluminum Forging in Rail Transportation

As the rail transportation industry continues to evolve, driven by the need for increased efficiency, sustainability, and passenger comfort, the use of aluminum forgings is expected to grow significantly. Advancements in materials science and forging technology are leading to the development of new aluminum alloy compositions with even better properties. For example, the incorporation of advanced alloying elements and the use of nanotechnology are being explored to further improve the strength – to – weight ratio, fatigue resistance, and corrosion resistance of aluminum alloys.

In addition, advanced forging techniques, such as precision forging and near – net – shape forging, are becoming more prevalent. These techniques allow for the production of aluminum forgings with higher dimensional accuracy, better surface finish, and improved mechanical properties, reducing the need for post – forging machining and increasing production efficiency. In the future, as the demand for high – speed, long – distance, and environmentally friendly rail transportation continues to rise, aluminum forgings will play an even more crucial role in enabling the development of innovative rail vehicle designs and infrastructure solutions. By investing in research and development and promoting the adoption of new aluminum forging technologies, we can ensure that our rail transportation systems remain at the forefront of global innovation.