Alloy Steel Forging: Material Selection and Preprocessing

The foundation of successful alloy steel forging for industrial components begins with precise material selection and preprocessing. We carefully choose alloy steel grades based on the component’s intended application, considering factors like tensile strength, corrosion resistance, and temperature tolerance. Common selections include 4140 chromoly steel for high-strength parts and 4340 alloy steel for components requiring exceptional toughness. Before forging, we inspect raw materials for defects using ultrasonic testing, ensuring only quality stock proceeds to production. We then prepare the material through processes like descaling to remove surface oxides and cutting to precise billet sizes. Proper preprocessing prevents contamination during forging and ensures uniform heating. By matching the right alloy steel to each industrial component’s requirements and preparing materials meticulously, we establish the conditions necessary for consistent, high-quality forging results.

Alloy Steel Forging: Controlled Heating for Optimal Workability

Controlled heating is a critical process in alloy steel forging that directly impacts component quality. We heat alloy steel billets in precision furnaces, carefully monitoring temperatures to reach the optimal forging range—typically between 1,100°C and 1,250°C depending on the alloy grade. This temperature range softens the steel sufficiently for deformation while preserving its metallurgical properties. We use computerized temperature control systems to maintain uniformity, ensuring every section of the billet reaches the ideal temperature. For complex industrial components like gear blanks or valve bodies, we employ gradient heating techniques to achieve varying levels of workability in different sections. Proper heating prevents overheating, which can cause grain growth and weaken the material, or underheating, which increases forging force requirements and risks cracking. By mastering heating parameters, we ensure the alloy steel responds predictably during deformation.

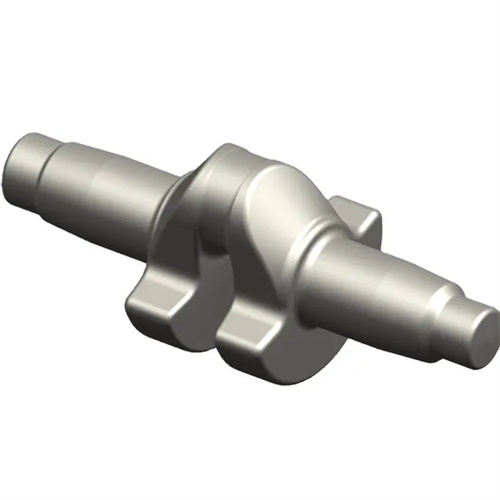

Alloy Steel Forging: Precision Forming Techniques

Precision forming techniques lie at the heart of producing high-quality industrial alloy steel components. We utilize various forging methods based on component complexity, including open-die forging for large, simple shapes and closed-die forging for intricate parts with tight tolerances. Our hydraulic and mechanical presses deliver controlled pressure—ranging from hundreds to thousands of tons—to shape the heated alloy steel into the desired form. For industrial components requiring precise dimensions, like bearing races or connecting rods, we employ impression-die forging, where the die cavities guide material flow. We continuously monitor deformation rates during forging, adjusting pressure and timing to prevent defects like laps or folds. By combining advanced press technology with skilled operator oversight, we ensure each forged component achieves the correct geometry while maintaining the alloy steel’s enhanced mechanical properties through proper grain flow alignment.

Alloy Steel Forging: Heat Treatment for Property Enhancement

Heat treatment is an essential post-forging process that enhances the mechanical properties of alloy steel industrial components. After forging, we subject components to carefully controlled heat treatment cycles tailored to the specific alloy grade. This typically involves annealing to relieve internal stresses, normalizing to refine grain structure, and quenching and tempering to achieve desired hardness and toughness balances. For high-wear industrial parts like crusher jaws or hydraulic piston rods, we apply surface hardening treatments such as carburizing or nitriding to create a hard outer layer while maintaining a ductile core. We use programmable furnaces to ensure precise temperature control and uniform cooling rates, critical for achieving consistent results. Proper heat treatment transforms the forged alloy steel’s microstructure, maximizing strength, wear resistance, and fatigue life—properties essential for reliable performance in industrial machinery.

Alloy Steel Forging: Surface Finishing and Inspection

Surface finishing and rigorous inspection ensure alloy steel forgings meet industrial component specifications. After heat treatment, we perform surface finishing processes like grinding, polishing, or shot blasting to achieve required surface roughness and remove any scale or burrs. For components requiring corrosion resistance, we apply protective coatings such as zinc plating or paint, with proper surface preparation ensuring adhesion. Inspection is multi-layered: we use coordinate measuring machines (CMMs) to verify dimensional accuracy, ultrasonic testing to detect internal defects, and hardness testing to confirm material properties. For critical industrial components like pressure vessel flanges or turbine shafts, we conduct magnetic particle inspection to identify surface cracks. These finishing and inspection processes ensure each forged component not only meets dimensional requirements but also possesses the surface quality and structural integrity necessary for safe, reliable operation in industrial environments.

Alloy Steel Forging: Quality Control and Process Validation

Comprehensive quality control and process validation ensure consistency in alloy steel forging for industrial components. We implement statistical process control (SPC) throughout production, monitoring key parameters like forging temperature, pressure, and cycle time to maintain process stability. Our quality management system includes documented procedures for every process step, from material receipt to final inspection. We conduct regular process validation studies, comparing actual component performance against design requirements through destructive and non-destructive testing. For high-criticality industrial components, we perform fatigue testing and load simulation to verify performance under real-world conditions. We also maintain detailed records of each component’s production history, enabling full traceability from raw material to finished product. This rigorous quality control framework ensures that our alloy steel forgings consistently meet the demanding performance and reliability standards required in industrial applications.