Aluminum Forging vs. Casting: Fundamental Process Principles

The most fundamental difference between aluminum forging and casting lies in how we shape the material. In aluminum forging, we start with solid aluminum billets, heat them to malleable temperatures (typically 350-500°C), and use mechanical pressure to deform the metal into the desired shape. This process relies on plastic deformation, where the aluminum’s atomic structure rearranges without melting. Casting, by contrast, involves melting aluminum alloy (at around 660°C) and pouring the molten metal into molds, where it cools and solidifies into the final shape. Forging requires significant force—from hydraulic presses or hammering—to shape the metal, while casting depends on gravity or pressure to fill mold cavities. These core differences result in distinct material characteristics: forging creates dense, refined microstructures through mechanical working, while casting produces more porous structures with coarser grains due to solidification. Understanding these process fundamentals helps us select the right method for specific application requirements.

Aluminum Forging vs. Casting: Material Strength and Integrity

Aluminum forging consistently produces components with higher strength and structural integrity compared to casting. The mechanical deformation in forging compresses the aluminum’s grain structure, eliminating internal voids and aligning grains along stress paths. This results in tensile strengths 20-50% higher than equivalent cast aluminum parts, with significantly better impact resistance and fatigue life. Cast aluminum, while suitable for many applications, often contains porosity, shrinkage cavities, or oxide inclusions formed during solidification—defects that weaken the material and create potential failure points. We’ve tested 6061 aluminum parts, finding forged versions achieve ultimate tensile strengths around 45,000 psi compared to 30,000 psi for cast parts of the same alloy. For safety-critical components like automotive suspension parts or aerospace brackets, the superior material integrity of aluminum forging ensures reliable performance under extreme conditions where cast parts might fail prematurely.

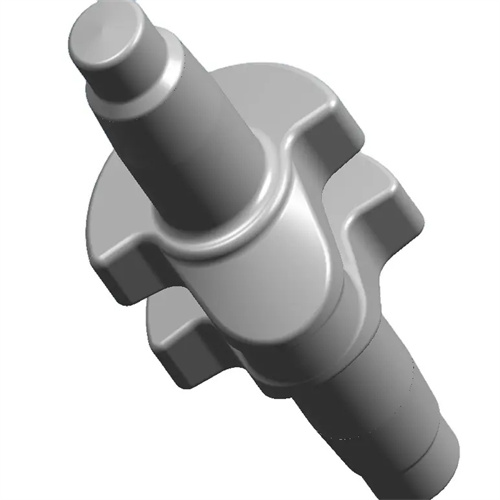

Aluminum Forging vs. Casting: Design Capabilities and Limitations

Aluminum forging and casting offer different design capabilities, each with unique advantages and limitations. Casting excels at producing complex geometries with internal cavities, thin walls, and intricate details that would be difficult or impossible to achieve through forging. Molds can create undercuts, hollow sections, and fine surface features in a single casting operation. Aluminum forging, while more limited in shape complexity, excels at producing components with varying cross-sections and thick-to-thin transitions that require high strength. Forging cannot create true internal cavities but can produce near-net shapes with integrated features like flanges and bosses. We typically recommend casting for low-stress, highly detailed parts like decorative trim or housings, while aluminum forging is better suited for structural components where strength and durability matter more than complex geometry. Both processes allow for design optimization, but their different capabilities guide material selection for specific part functions.

Aluminum Forging vs. Casting: Production Volume and Cost Considerations

Production volume significantly impacts the cost-effectiveness of aluminum forging versus casting. Casting requires mold creation, which has lower initial tooling costs for simple designs, making it economical for low-volume production (fewer than 1,000 units). However, aluminum forging involves higher upfront tooling expenses for die manufacturing but becomes more cost-effective at higher volumes due to faster production cycles and reduced material waste. For volumes exceeding 5,000 units, we often see forging costs per part become competitive or lower than casting. Casting also incurs higher scrap rates (typically 10-15%) due to solidification defects, while forging maintains scrap rates below 5%. Additionally, forged aluminum parts require less post-processing than cast parts, which often need machining to correct surface defects. When evaluating total production costs, we consider not just unit price but also material utilization, scrap rates, and finishing requirements to determine the most economical process for each production run.

Aluminum Forging vs. Casting: Lead Time and Production Speed

Lead times and production speeds differ substantially between aluminum forging and casting processes. Casting requires mold development, which can take 4-8 weeks for simple sand molds or 10-16 weeks for complex permanent molds. Once molds are ready, casting production rates vary from a few parts per hour for investment casting to hundreds per hour for high-pressure die casting. Aluminum forging involves die manufacturing that typically takes 6-12 weeks but offers faster per-part production times for high-volume runs, with automated forging presses producing dozens of parts per hour. For prototyping or low-volume needs, casting often provides shorter initial lead times, especially with rapid prototyping casting methods. However, for ongoing production, forging’s faster cycle times and higher throughput make it advantageous for meeting tight delivery schedules. We balance these factors when recommending processes, using casting for quick-turn prototypes and aluminum forging for sustained production requiring consistent quality.

Aluminum Forging vs. Casting: Surface Finish and Post-Processing Needs

Aluminum forging and casting require different levels of post-processing to achieve final part quality. Cast aluminum parts often have rough surface finishes (typically 125-250 μin Ra) due to mold release agents and solidification effects, requiring extensive machining or polishing for critical surfaces. They may also need heat treatment to improve mechanical properties that are inherently lower than forged parts. Aluminum forging produces smoother as-forged surfaces (63-125 μin Ra) with tighter dimensional tolerances, reducing the need for post-processing. Forged parts still require heat treatment to maximize strength but benefit from a more uniform microstructure that responds predictably to thermal processing. The dense structure of forged aluminum also provides better substrate quality for surface treatments like anodizing or painting, with fewer defects requiring filling or repair. While both processes can achieve high-quality finishes, aluminum forging minimizes post-processing steps, reducing production time and costs while ensuring more consistent final part quality.